Conveyor Belt cold splicing types

The conveyor belt is a very important part in the whole conveyor machine. Daily turning to maintain normal productivity. So it is also easily damaged or broken, it will influence the running of the conveyor when you stop the machine to repair the belt. In order to do our best to save repair time, Ramimtech invests money to establish our laboratory and research power in this field.

After our research and testing, we established our own repair system to solve the different problems in different situations.

1. Repair Strip: This is the most traditional method in various industries. Suitable for the damaged part only on the surface of the belt, but does not penetrate. Long-form damage, such as longitudinal tear, always needs a strip to repair.

2.Repair patch: suitable for the damaged part on the surface of the belt only. Small damaged or broken patches prefer to use this type of solution.

3.Rubber dust repair: suitable for a large part of the damage, especially the belt has a hole or a large damage area. It is also very easy to operate for harsh environments with short repair time. Big hole or break can choose this method. Dry very fast. It is powdered, when you use it you can put the powder in a container and start heating it. When the temperature more than 65℃ it will start to melt to gel. And then you can fill the gel on the broken part, dry in 10 minutes.

4.Rubber Gel Repair: Easy-to-grab gasket to detect holes or penetrable belt damage. It is also very easy to operate for harsh environments with short repair time. Dry very fast.

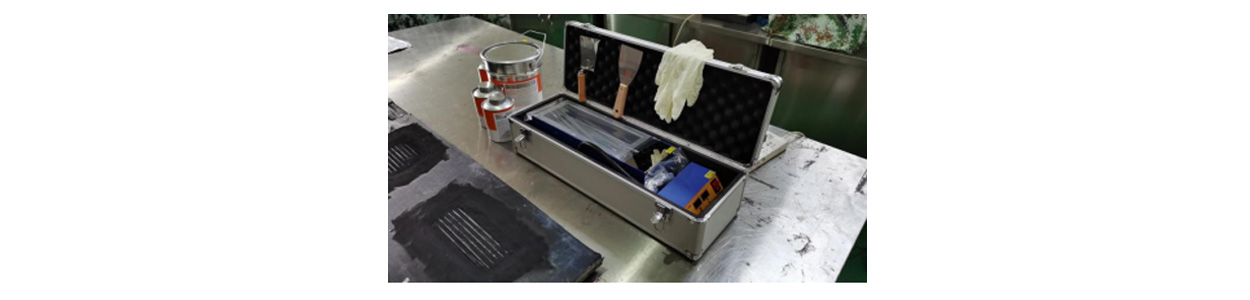

Repair of the rubber cement group: With cleaning solvent, metal primer and rubber reconstruction liquid. Take and store easily. The thin liquid can be well matched with different types of belts.

5.Mechanical belt fastener: It is a type of carbon steel materials belt clip which can be well and quickly repair the large or long damage of the conveyor belt fast and easily even without professional training or plan. Different size can be used for different thickness of conveyor belt and damage part. Conveyor can ready to run after finished repair.

6.Seamless rubber conveyor belt repair patch:

6.Seamless rubber conveyor belt repair patch:

Better combined and fit the conveyor belt because the repair patch also rubber, so rubber to rubber will be easier to adapt to the belt damage part. There also have screws in the joint part, can tightly fit with the rubber belt fabric core. Conveyor can ready to run after finished repair.

Please choose any suitable way to repair according to the exact situation of your belt. There is always a method that can help you quickly get back to productivity. Time is money.