Ceramic Al2O3 Belt Cleaner

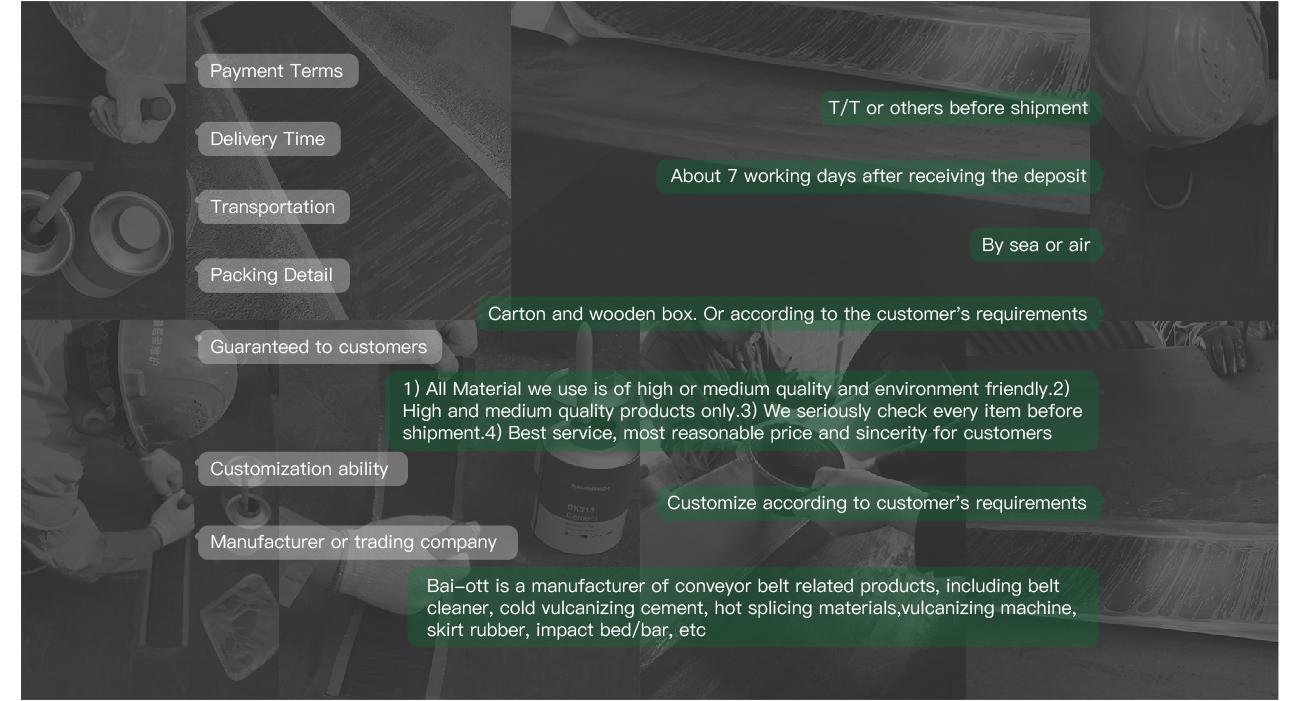

Brand: BAI-OTT or OEM

Belt Width: 650mm-2200mm

Feature: Wear-Resistant,Adjustment,Design

Tensile Strength: 53

Material: Alloy, Ceramic

MOQ: 1 Set

Sample: Provide

Product Inspection:Available

Lead time: Ready to ship in stock

View more Conveyor Belt Cleaner from BAI-OTT

Description

Ceramic Al2O3 Belt Cleaner

Introduce new products produced by foreign advanced technology, and apply for patents in China. The main material of the new ceramic belt cleaner is alumina ceramic, which has good mechanical strength, wear resistance and high temperature resistance. It changes the working mode of the existing old-fashioned scraper cleaners in China and improves the cleaning accuracy.

BAI-OTT is a professional manufacturer of conveyor belt cleaner and scraper in China. The cleaners we design and manufacture are Light duty PU primary belt Cleaner, Heavy duty primary PU belt scraper, Constant pressure primary belt sweeper, Alloy primary belt cleaner (H type), Ceramic belt cleaner, Medium-sized primary conveyor sweeper, secondary scraper sweeper, second alloy sweeper,second constant pressure sweeper, universal alloy sweeper, Tail V-plow conveyor sweeper, central I-type conveyor cleaner, electric roller brush cleaner and sweeper blade.

| Order No. | Product Name | Belt Width(mm) | Ceramic No. | Installation Site |

| 7855165 | Ceramic Al2O3 Belt Cleaner | 650 | 20 pcs | Head Unloading Drum |

| 7855180 | Ceramic Al2O3 Belt Cleaner | 800 | 25 pcs | Head Unloading Drum |

| 7855110 | Ceramic Al2O3 Belt Cleaner | 1000 | 30 pcs | Head Unloading Drum |

| 7855112 | Ceramic Al2O3 Belt Cleaner | 1200 | 36 pcs | Head Unloading Drum |

| 7855114 | Ceramic Al2O3 Belt Cleaner | 1400 | 43 pcs | Head Unloading Drum |

| 7855116 | Ceramic Al2O3 Belt Cleaner | 1600 | 48 pcs | Head Unloading Drum |

| 7855118 | Ceramic Al2O3 Belt Cleaner | 1800 | 52 pcs | Head Unloading Drum |

| 7855120 | Ceramic Al2O3 Belt Cleaner | 2000 | 58 pcs | Head Unloading Drum |

| 7855122 | Ceramic Al2O3 Belt Cleaner | 2200 | 64 pcs | Head Unloading Drum |

Advantage

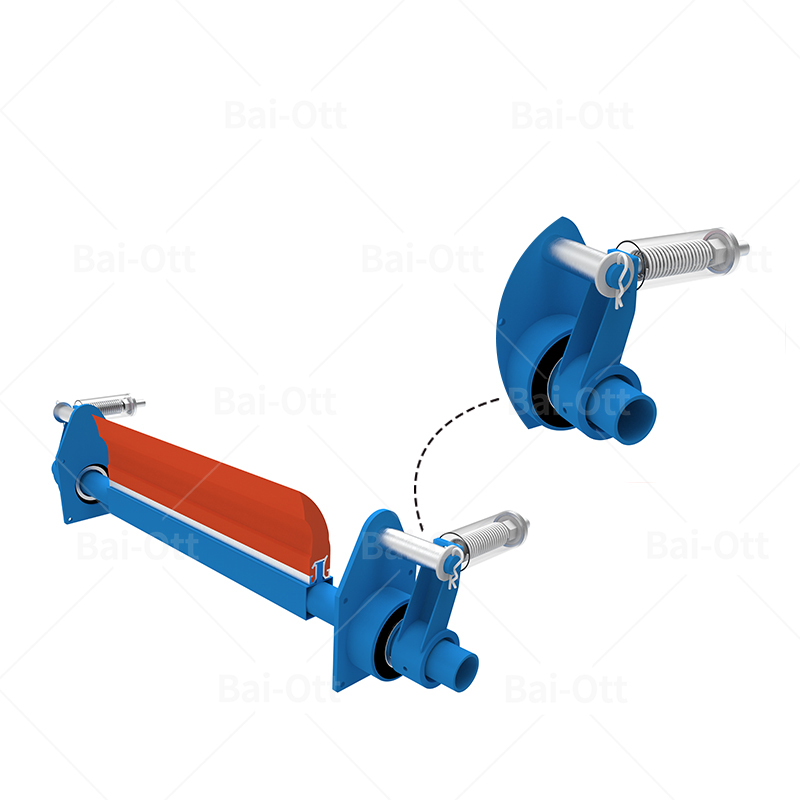

The ceramic belt cleaner is composed of industrial ceramic blocks (AL203). Its Rockwell hardness can reach 85-90, and its wear resistance is 5 to 10 times that of steel. which is incomparable to polyurethane cleaners and alloy cleaners of.

Depending on the conveyed material, the service life is more than ten times that of the alloy cleaner.

The surface of the ceramic cleaner is smooth and wears little to the belt, which greatly improves the life of the main auxiliary equipment of the belt conveyor, such as belts, drums and idlers, reduces the labor workload of the post personnel, reduces the production cost and improves the production efficiency.

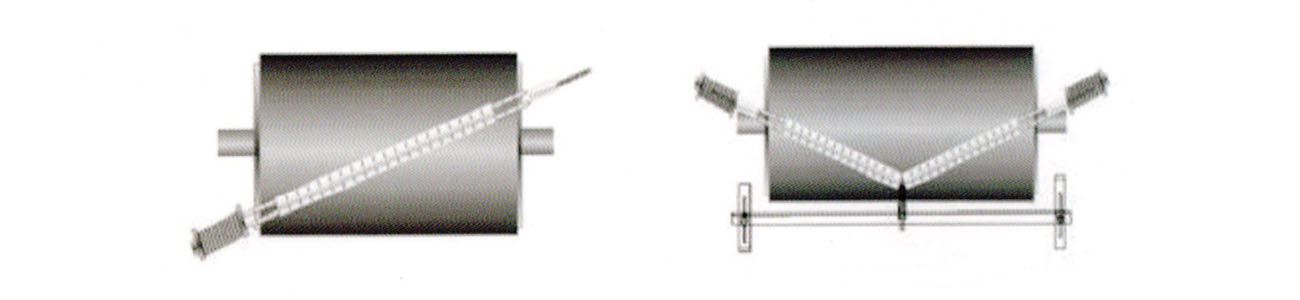

The ceramic belt cleaner is installed obliquely on the roller part, and will be closely attached to the belt conveyor to form point contact, which is particularly effective for conveying wet and sticky materials, which is incomparable to the scraper cleaner.

The ceramic belt cleaner can be installed on belt conveyors in various working environments. It only takes about half an hour to install, and it is easy to maintain.

Specifications