Non working PU I-Plow Belt Cleaner Machine

Brand: BAI-OTT or OEM

Belt Width: 650mm-2200mm

Feature: Wear-Resistant,Adjustment,Design

Tensile Strength: 53

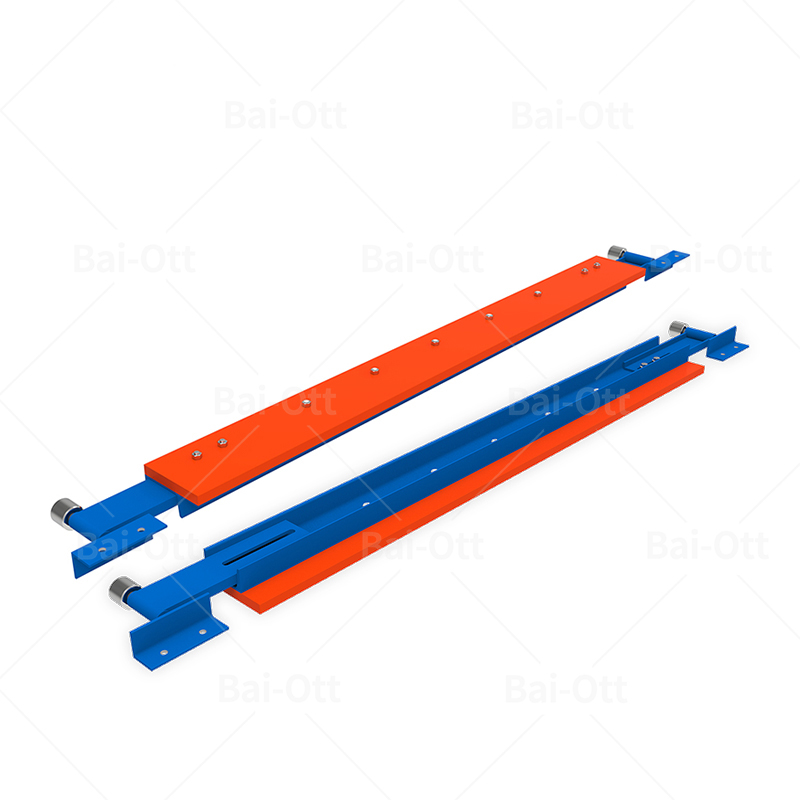

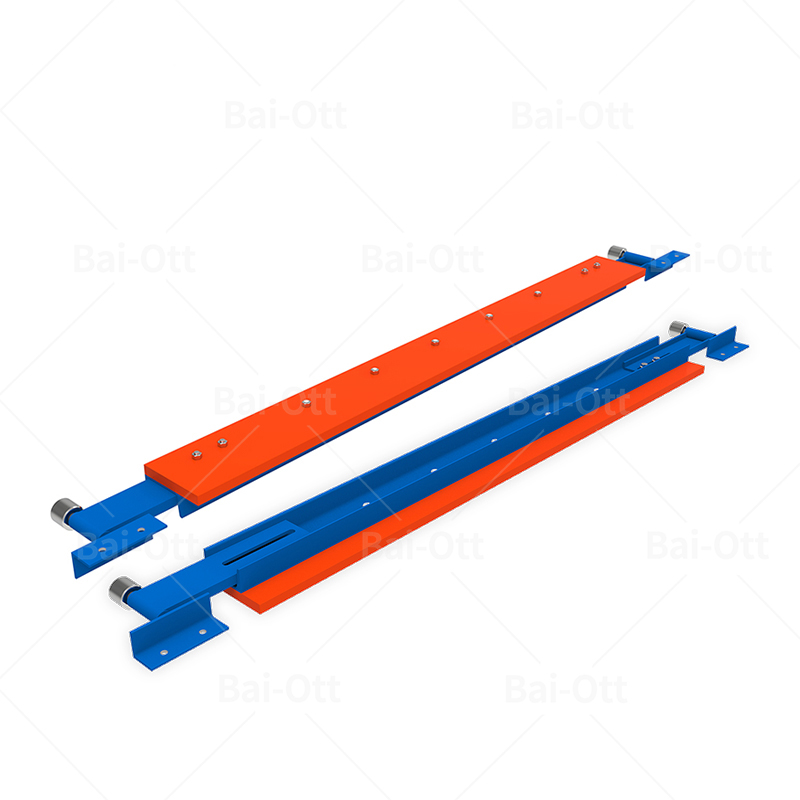

Material: Polyurethane+Steel

Installation Site: Return Belt Tail Drum

MOQ: 1 Set

Sample: Provide

Product Inspection:Available

Lead time: Ready to ship in stock

View more Conveyor Belt Cleaner from BAI-OTT

Description

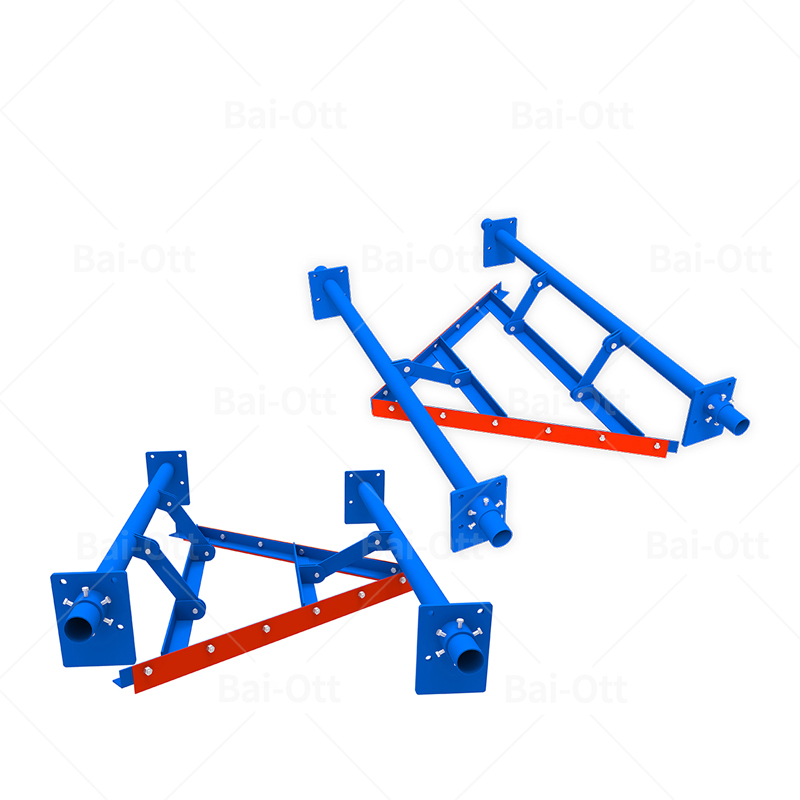

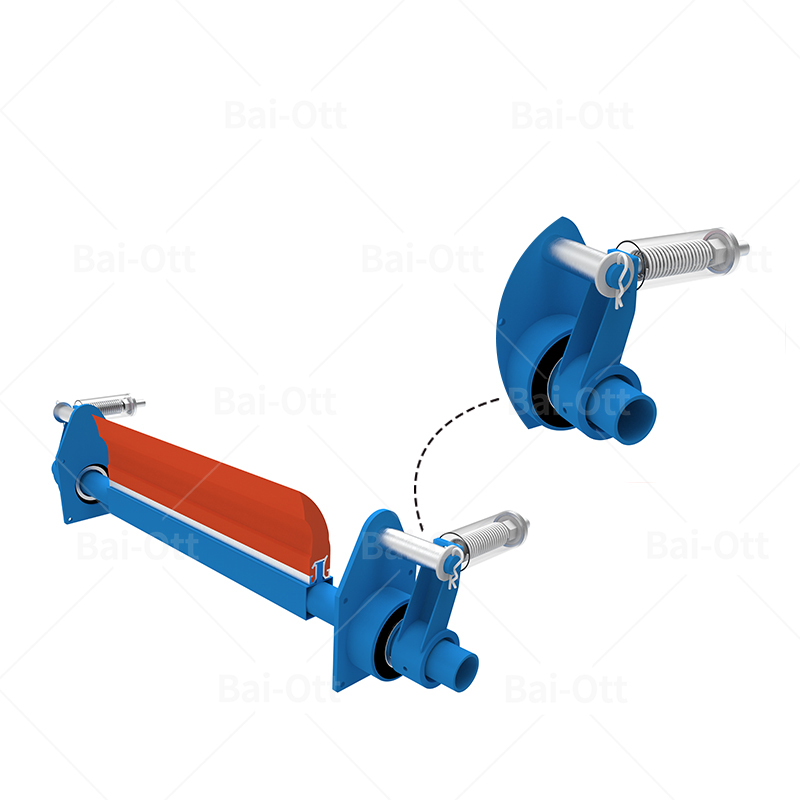

Abrasion Resistant Non working PU I-Plow Belt Cleaner Machine

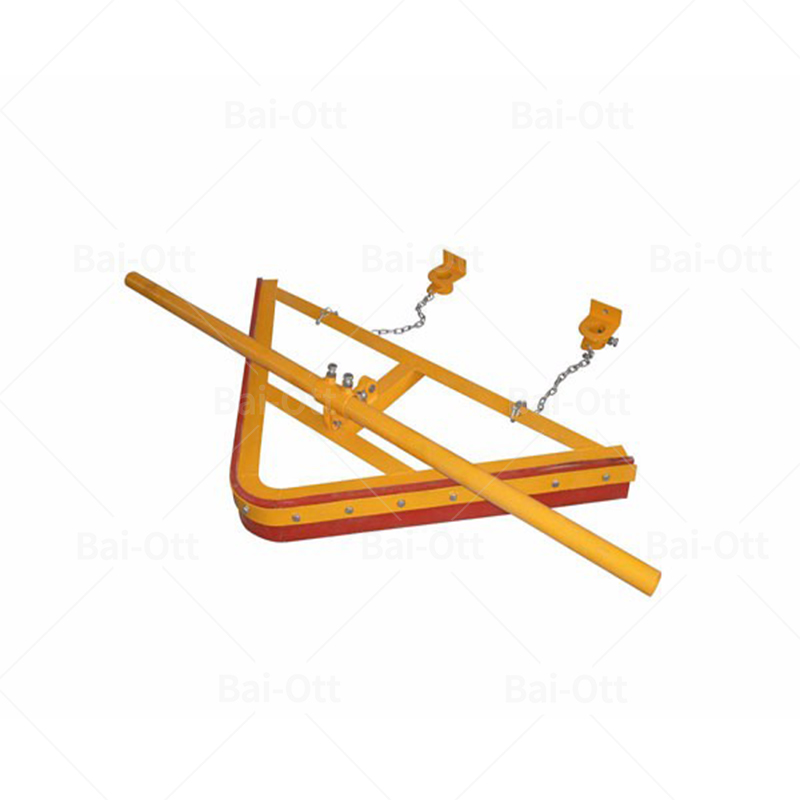

I-Plow Belt Cleaner Machine is installed at the tail of the belt conveyor, 1.5m-3m away from the tail wheel on the flat surface of the return belt, the blade is attached to the non-working surface of the belt by the tensioner spring, and the spilled materials are cleaned up to prevent the tail material from entering the tail wheel, causing belt damage and deviation. Bidirectional ""I-type"" cleaners are suitable for belt conveyors operating in both directions.

It is installed on the flat surface above the non-bearing surface of the return belt running in both directions. Under the action of the tensioner, the blade is obedient to the surface of the return belt to clean the material on the belt, which is conducive to the normal operation of the belt and the tail wheel, to improve the deviation of the belt caused by the phenomenon.

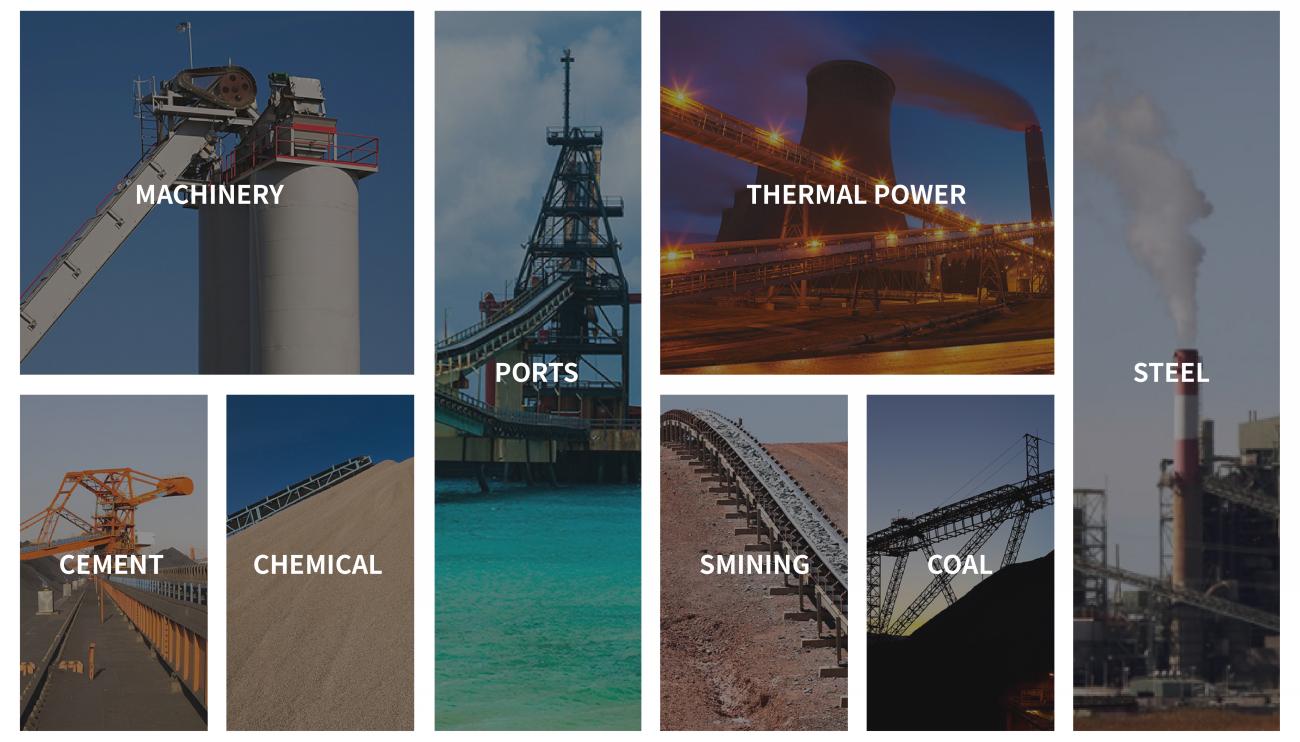

BAI-OTT is a professional manufacturer of conveyor belt cleaner and scraper in China. The cleaners we design and manufacture are Light duty PU primary belt Cleaner, Heavy duty primary PU belt scraper, Constant pressure primary belt sweeper, Alloy primary belt cleaner (H type), Ceramic belt cleaner, Medium-sized primary conveyor sweeper, secondary scraper sweeper, second alloy sweeper,second constant pressure sweeper, universal alloy sweeper, Tail V-plow conveyor sweeper, central I-type conveyor cleaner, electric roller brush cleaner and sweeper blade. As we know,Primary belt cleaner is the most important part in conveyor belt cleaning system. It located closely under the head drum to make the first step of cleaning for the whole system. 90% residule materials can be cleaned by it in transportation. So it is necessary to guarantee the strength of frame and tensioners, the wear abrasive ability of blades, which influence products effect lot.

| Order No. | Product Name | Belt Width(mm) | Blade Width(mm) | Installation Site |

| 7855165 | I-Plow Belt Cleaner Machine | 650 | 650 | Return Belt Tail Drum |

| 7855180 | I-Plow Belt Cleaner Machine | 800 | 800 | Return Belt Tail Drum |

| 7855110 | I-Plow Belt Cleaner Machine | 1000 | 1000 | Return Belt Tail Drum |

| 7855112 | I-Plow Belt Cleaner Machine | 1200 | 1200 | Return Belt Tail Drum |

| 7855114 | I-Plow Belt Cleaner Machine | 1400 | 1400 | Return Belt Tail Drum |

| 7855116 | I-Plow Belt Cleaner Machine | 1600 | 1600 | Return Belt Tail Drum |

| 7855118 | I-Plow Belt Cleaner Machine | 1800 | 1800 | Return Belt Tail Drum |

| 7855120 | I-Plow Belt Cleaner Machine | 2000 | 2000 | Return Belt Tail Drum |

| 7855122 | I-Plow Belt Cleaner Machine | 2200 | 2200 | Return Belt Tail Drum |

Further Dimensions on Demand.

Advantage

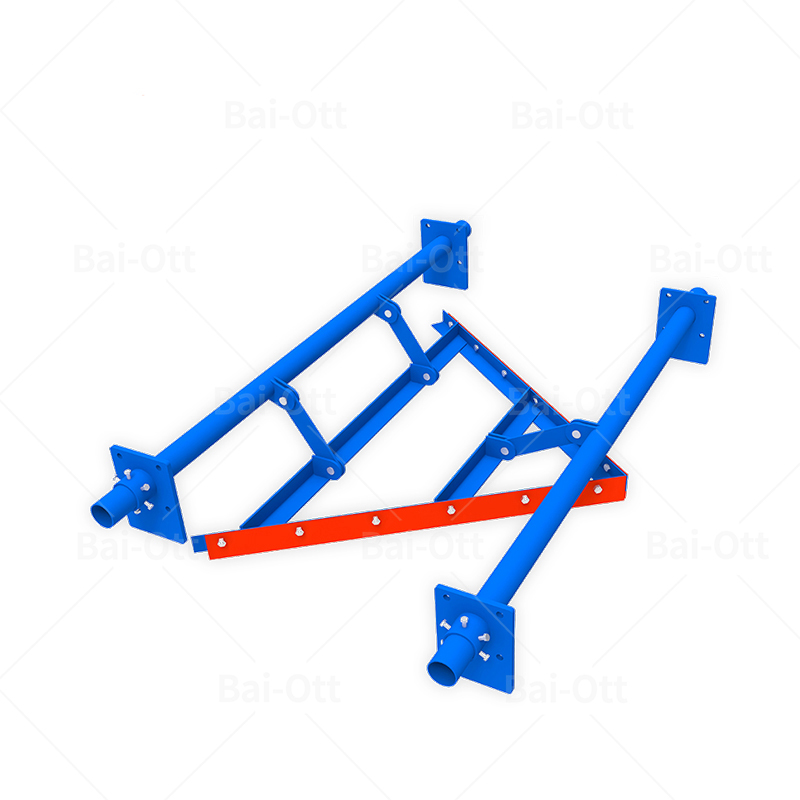

The cleaning blade is made of high-strength polyurethane, which has high strength, high wear resistance, high elasticity, low friction coefficient, will not cause damage to the conveyor belt, and has a long service life.

After the blade is worn, the blade compensation can be automatically adjusted according to the self-weight of the cleaner.

The latest spring tensioning style is optional, which can make the cleaner better fit the conveyor belt, and the cleaning effect is more stable and efficient.

Specifications

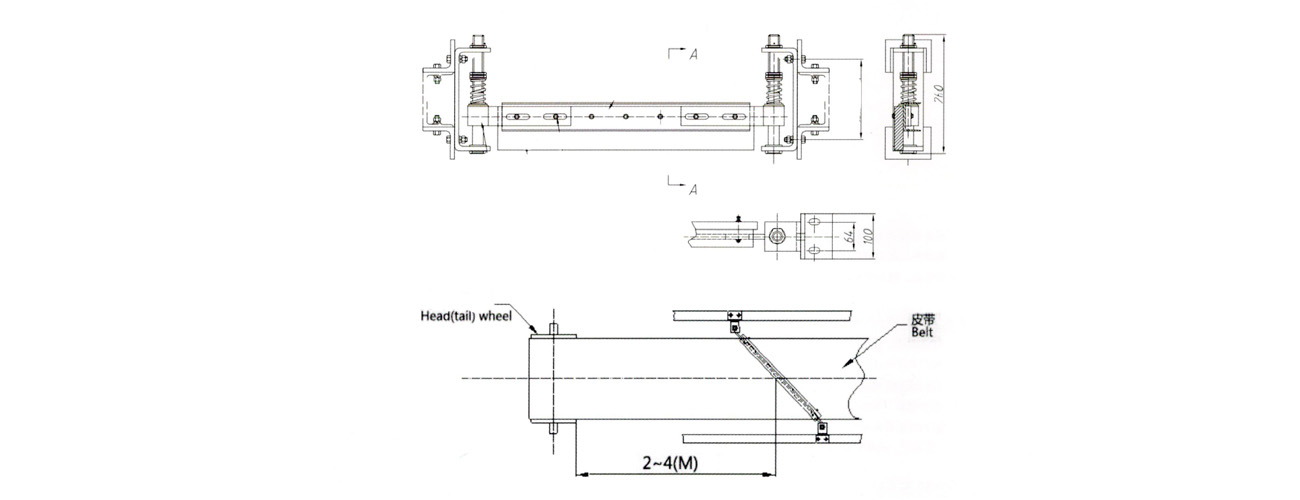

Outline design and installation drawings