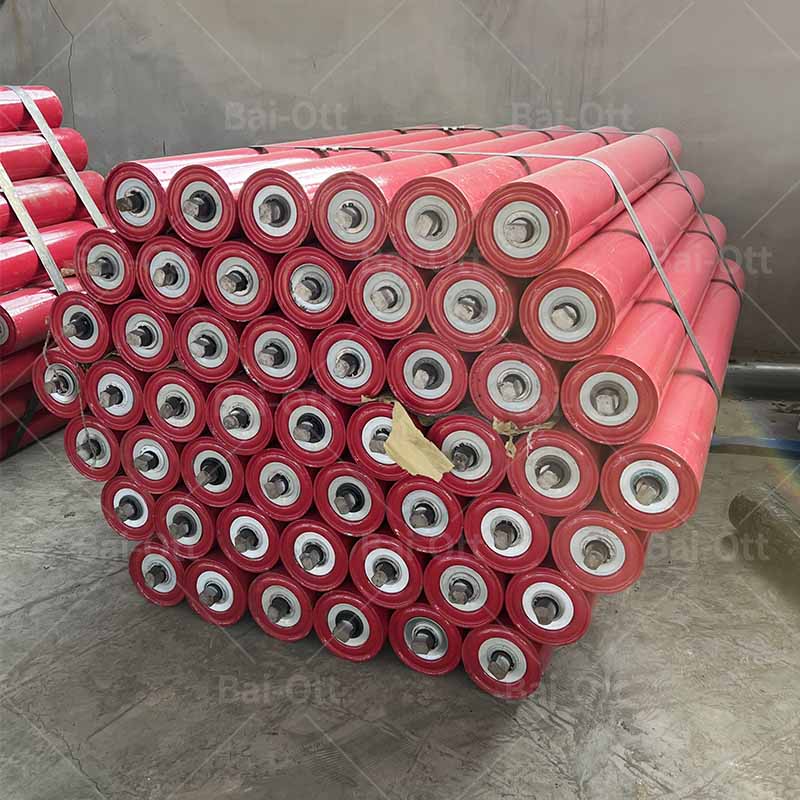

Conveyor Idler Roller Series

Brand: BAI-OTT or OEM

Feature: Abrasion and impact resistance

Size: Available

Material: Carbon steel+Rubber+Ceramic+PU+UHMWPE

Sample: Provide

MOQ: 10 Sets

Sample: Provide

Product Inspection:Available

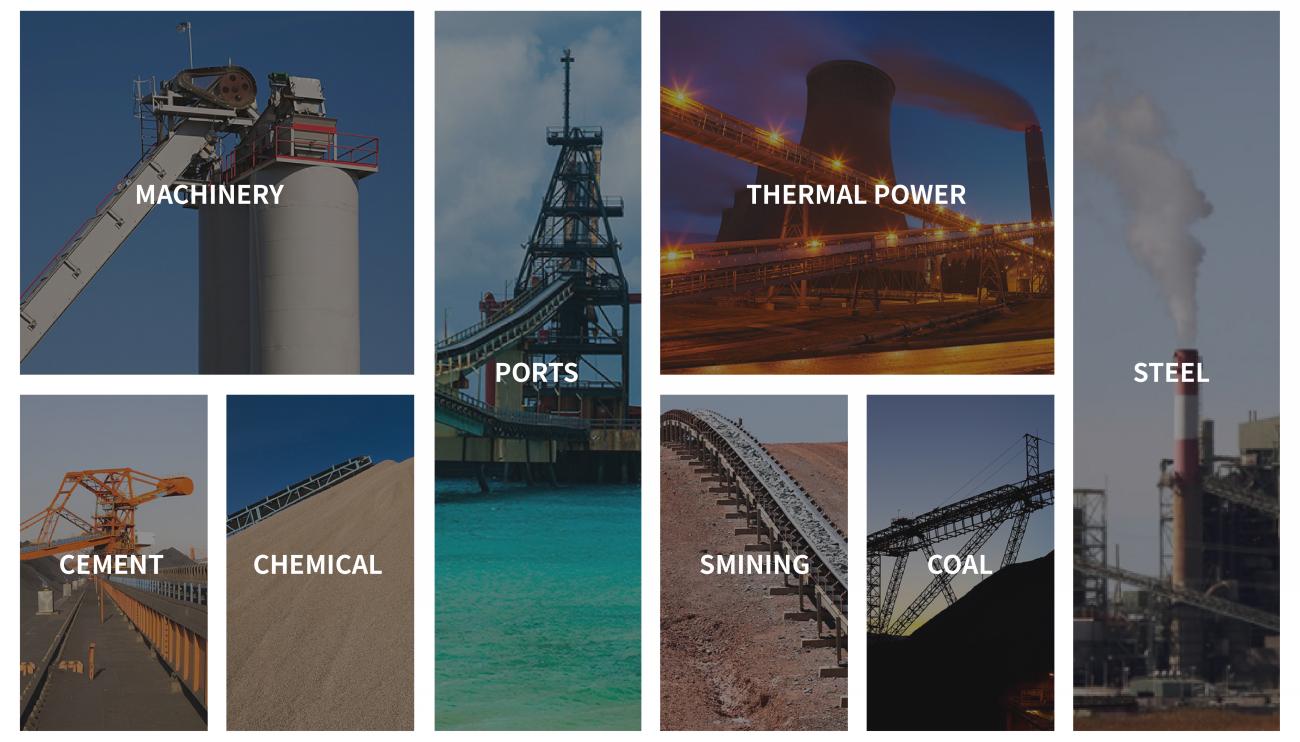

Application: Coal mines, Cement plants, Steel plants, Power plants and other factories

Lead time:Ready to ship in stock

View more Conveyor Idler Roller from BAI-OTT

Description

Conveyor Idler Roller Series

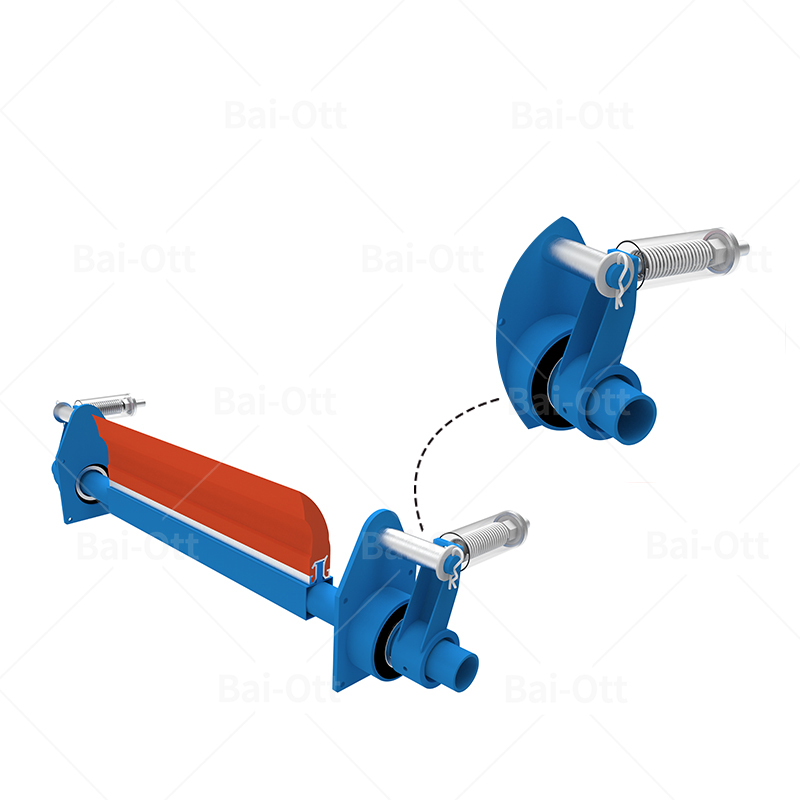

At present, our company's idler series products include many types,such as trough roller, up self-aligning roller , trough roller, trough down self-aligning idler, carry roller, impact roller, spiral roller,friction up self-aligning idler, parallel impact roller,parallel and up self-aligning roller,cleaning idler, tapping roller,conical roller, crown roller, and UHMWPE roller.Our company adopts international standard design and manufacturing technology to improve the design and manufacturing of idler to a higher level. The idler has the minimum rotation resistance, the longest service life, small maintenance workload and high bearing capacity. The roller seal is specially designed based on the characteristics of foreign and domestic labyrinth seal. It is filled with lithium based ester resistant to high speed, high temperature and ultra-low temperature, so as to effectively prevent the erosion of impurities, water and air to the inside of the roller.

Factors affecting the performance of idler

Idler is an important part of belt conveyor, and its quality affects the service life of belt conveyor directly. In order to produce a high-quality idler, we must strictly control the structure, the selection of parts and materials and the manufacturing process. Idler is one of the key components affecting the use effect of conveyor. In belt conveyor, idler is used to support conveyor belt and cargo load, and ensure that the sag of conveyor belt is within the design limit. In the design of belt conveyor, the selection and quantity of idler are important factors on the normal use, stable operation, maintenance cost, power consumption and machine price of belt conveyor.

With the continuous improvement of manufacturing technology, the machining accuracy of idler is no-longer the main factor that affect the service life of idler. Through investigation and analysis, it is found that the service life of idler bearing is the main factor affecting the service life of idler. The service life of the bearing mainly depends on the load, the quality of the bearing and the lubrication condition. Among these three factors, the lubrication condition of the bearing is the main reason affecting the service life of the bearing. The idler generally operates in a humid and dusty environment. Under the condition of high-speed operation, the internal friction will inevitably generate heat and the positive pressure of bearing self weight on the idler.When the idler stops running, the air pressure in the bearing sealing cavity decreases with the decrease of temperature, resulting in the suction process. With the suction, especially in the convex arc section, at present, most calculations regard the intermediate idler as a process, and a large number of dust particles enter to the bearing sealing cavity, resulting in the pollution of lubricating grease, so as to speed up the wear of the bearing. At the same time, since the grease is gradually reduced with the occurrence of vaporization, after a certain degree, the bearing will operate in a friction state, which is bound to aggravate the wear of the bearing and greatly shorten the service life of the idler.

| Order No. | Product Name | Belt Width(mm) | Diameter(mm) | Length(mm) |

| 382501 | Trough Roller | 500-1800 | 60-160 | 190-3000 |

| 382502 | Up Self-aligning Roller | 500-1800 | 60-160 | 190-3000 |

| 382503 | Trough Roller | 500-1800 | 60-160 | 190-3000 |

| 382504 | Trough Down Self-aligning Idler | 500-1800 | 60-160 | 190-3000 |

| 382505 | Carry Roller | 500-1800 | 60-160 | 190-3000 |

| 382506 | Impact Roller | 500-1800 | 60-160 | 190-3000 |

| 382507 | Spiral Roller | 500-1800 | 60-160 | 190-3000 |

| 382508 | Friction Up Self-aligning Idler | 500-1800 | 60-160 | 190-3000 |

| 382509 | parallel Impact Roller | 500-1800 | 60-160 | 190-3000 |

| 382510 | Parallel and Up Self-aligning Roller | 500-1800 | 60-160 | 190-3000 |

| 382511 | Cleaning Idler | 500-1800 | 60-160 | 190-3000 |

| 382512 | Tapping Roller | 500-1800 | 60-160 | 190-3000 |

| 382513 | Conical Roller | 500-1800 | 60-160 | 190-3000 |

| 382514 | Crown Roller | 500-1800 | 60-160 | 190-3000 |

| 382515 | UHMWPE Roller | 500-1800 | 60-160 | 190-3000 |

Further Dimensions on Demand.

Advantage

Stable operation, stable quality and maintenance free.

Small diameter jump, smooth rotation and long service life.

Multi channel labyrinth seal and prevent the invasion of dust and water.

High precision special steel pipe ensures low vibration and low noise of idler.

Specifications

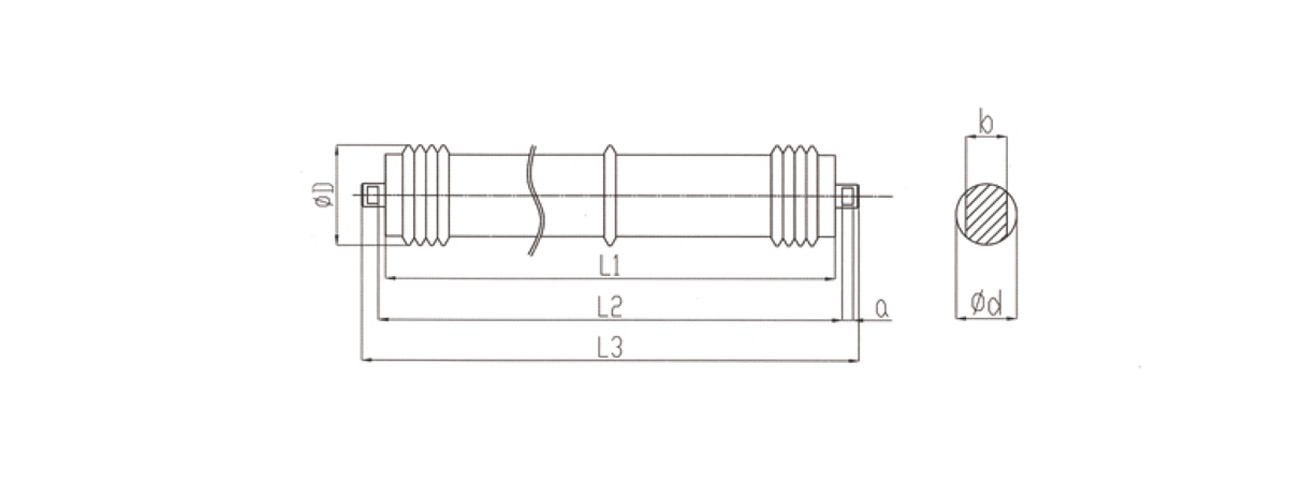

| MODEL | D | d | BEARING NO. | L1 | L2 | L3 | b | a | Belt Width(B) |

| 89*600 | 89 | 20 | 6204zz | 600 | 610 | 628 | 14 | 6 | 500/1000 |

| 89*750 | 750 | 760 | 778 | 650 | |||||

| 89*950 | 950 | 960 | 978 | 800 | |||||

| 89*1150 | 1150 | 1160 | 1178 | 1000 | |||||

| 89*600 | 25 | 6205zz 6305zz | 600 | 610 | 634 | 18 | 8 | 500/1000 | |

| 89*750 | 750 | 760 | 784 | 650 | |||||

89*950 | 950 | 960 | 984 | 800 | |||||

89*1150 | 1150 | 1160 | 1184 | 1000 | |||||

108*600 | 108 | 20 | 6204zz | 600 | 610 | 634 | 14 | 6 | 500/1000 |

108*750 | 750 | 760 | 784 | 650 | |||||

108*950 | 950 | 960 | 984 | 800 | |||||

108*1150 | 1150 | 1160 | 1184 | 1000 | |||||

108*1400 | 1400 | 1410 | 1434 | 1200/2400 | |||||

108*1600 | 1600 | 1610 | 1634 | 1400 | |||||

108*600 | 25 | 6205zz 6305zz | 600 | 610 | 634 | 18 | 8 | 500/1000 | |

108*750 | 750 | 760 | 784 | 650 | |||||

108*950 | 950 | 960 | 984 | 800 | |||||

108*1150 | 1150 | 1160 | 1184 | 1000 | |||||

108*1400 | 1400 | 1410 | 1434 | 1200/2400 | |||||

108*1600 | 1600 | 1610 | 1634 | 1400 | |||||

108*600 | 30 | 6206zz 6306zz | 600 | 610 | 634 | 22 | 8 | 500/1000 | |

108*750 | 750 | 760 | 784 | 650 | |||||

108*950 | 950 | 960 | 984 | 800 | |||||

108*1150 | 1150 | 1160 | 1184 | 1000 | |||||

108*1400 | 1400 | 1410 | 1434 | 1200/2400 | |||||

108*1600 | 1600 | 1610 | 1634 | 1400 | |||||

133*750 | 133 | 25 | 6205zz 6305zz | 750 | 760 | 784 | 18 | 8 | 650 |

133*950 | 950 | 960 | 992 | 800 | |||||

133*1150 | 1150 | 1160 | 1192 | 1000 | |||||

133*1400 | 1400 | 1410 | 1442 | 1200/2400 | |||||

133*1600 | 1600 | 1610 | 1642 | 1400 | |||||

133*1800 | 1800 | 1810 | 1842 | 11 | 1600 | ||||

133*2000 | 2000 | 2010 | 2042 | 1800 | |||||

133*2200 | 2200 | 2210 | 2242 | 2000 | |||||

133*2500 | 2500 | 2510 | 2542 | 2200 |