Conveyor Idler Support

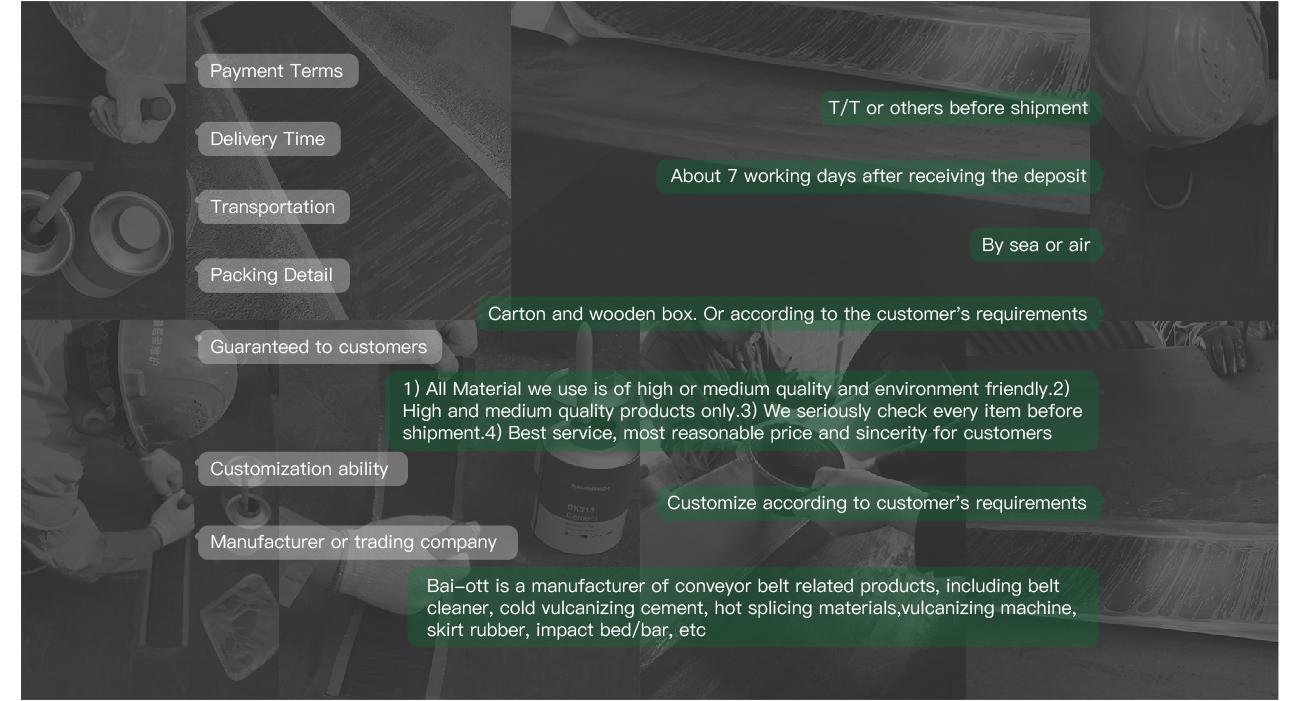

Brand: BAI-OTT or OEM

Feature: Abrasion and impact resistance

Size: Available

Material: Carbon steel+Rubber

Sample: Provide

MOQ: 10 Sets

Sample: Provide

Product Inspection:Available

Application: Coal mines, Cement plants, Steel plants, Power plants and other factories

Lead time:Ready to ship in stock

View more Conveyor Idler Roller from BAI-OTT

Description

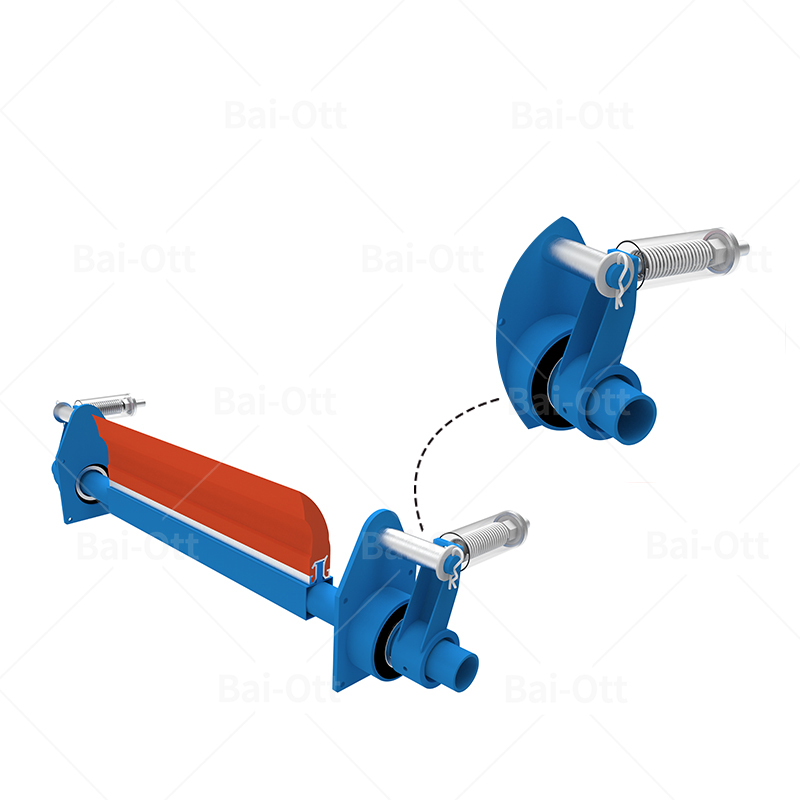

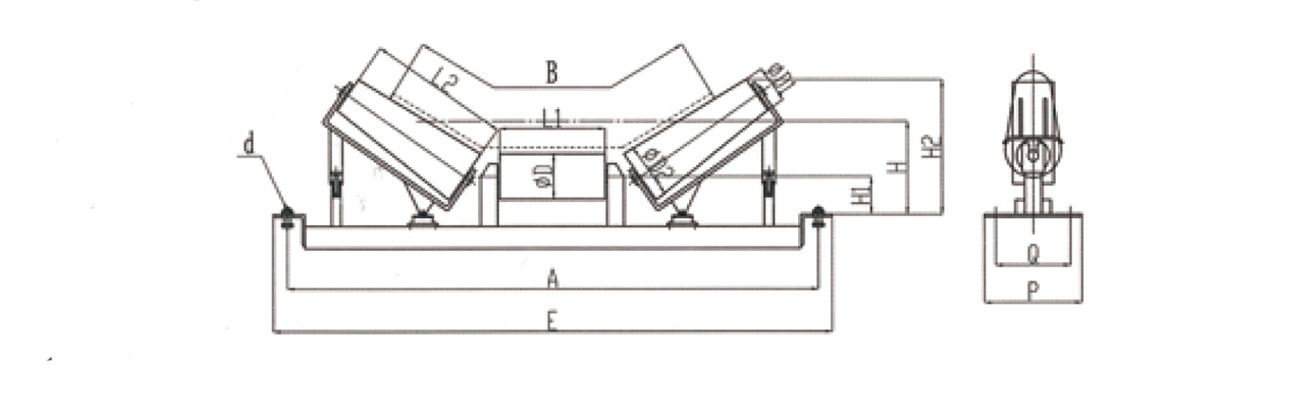

Idler support device:

The high-quality idler support device is not only a idler support device that is convenient to replace the idler, but also consists of deflectable idler support, pin shaft, machine body, idler, limit block and fasteners. The lower end of the support is connected with the upper end of the machine body with fasteners, the support is connected with the deflectable idler support with a pin shaft, and the deflectable idler support is provided with a idler. A clamping groove for rotating around the pin shaft is arranged on the deflectable idler support, the idler is installed in the clamping groove of the deflectable idler support, and a limit block for controlling the deflection angle is arranged on the deflectable idler support. The support or machine body is provided with a pin shaft around which the deflectable idler support can rotate. When the fasteners are removed, the deflectable idler support can rotate a certain angle around the horizontally fixed pin shaft under the control of the limit block. The grooved support belongs to a kind of idler support. Adopt advanced production technology to ensure product quality. The grooved idler removes the dirt on the belt, which has large feeding force and small resistance on the slope belt, and the effect is the best. The double section idler can reduce the re forming pressure point of the belt on the ceramic idler. The hollow device of the idler can make the stained objects fall off by itself, and the service life of the idler can be prolonged without touching the suction idler.

The idler support is used to carry the operation of the idler and make the materials on the conveyor belt run smoothly. It plays a great role in the conveyor. The specifications and models of the roller support produced by our company are b500mm-b2200mm, and the groove angle of the support is 20 °, 30 °, 35 ° and 45 °. According to the type, there are parallel upper and lower roller support, buffer roller support, transition roller support, self-aligning roller support, etc., which are divided into light, medium and heavy according to the bearing capacity Non standard design and production can also be carried out according to customer needs.

The support or machine body is provided with a pin shaft around which the deflectable idler support can rotate. When the fasteners are removed, the deflectable idler support can rotate a certain angle around the horizontally fixed pin shaft under the control of the limit block. The grooved support is a kind of idler support. Adopt advanced production technology to ensure product quality. The grooved idler removes the dirt on the belt, which has large feeding force and small resistance on the slope belt, and the effect is the best.

1. Grooved idler support has strong support, high flexibility, small friction and long service life.

2. Radial runout of grooved support; Flexibility; Axial displacement.

3. The groove support has five key points: dustproof, waterproof, axial bearing, impact resistance and service life.

4. It is installed on both sides of the conveyor belt to prevent the conveyor belt from deviation. Effectively make the tape run smoothly and reliably.

5. The center adjustment effect is remarkable, and the structure is simple, which can fully meet the needs of the development of modern operation.

Advantage

The self-aligning idler support has the advantages of strong support, high flexibility, small friction and long service life.

Radial runout of centering support; Flexibility; Axial displacement.

The self-aligning support has five key points: dustproof, waterproof, axial bearing, impact resistance and service life.

It is installed on both sides of the conveyor belt to prevent the conveyor belt from deviation. Effectively make the tape run smoothly and reliably.

The center adjustment effect is remarkable, and the structure is simple, which can fully meet the needs of the development of modern operation.

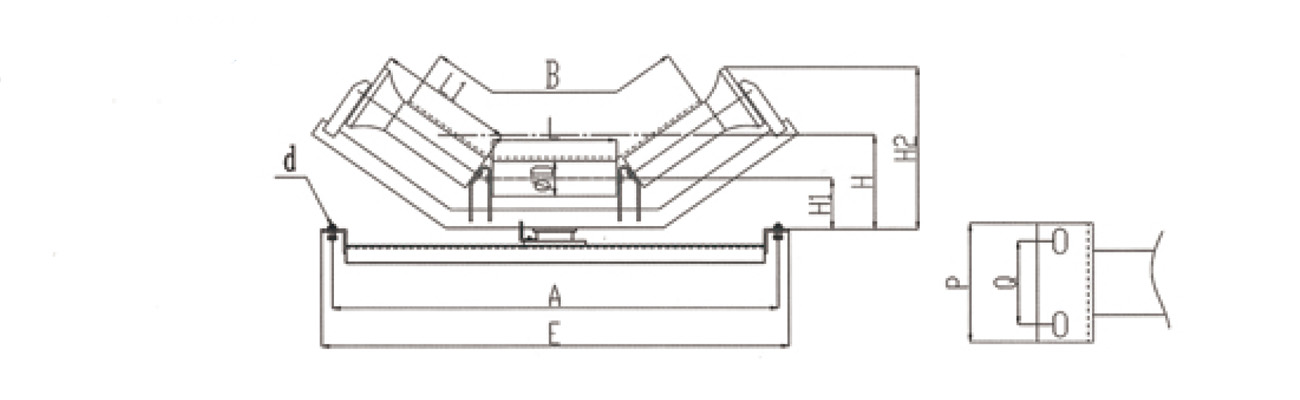

Specifications

Precautions during use:

Attention should be paid to adjusting the idler support during use, which can effectively prevent the deviation of the belt. In this way, it will not cause material leakage, abnormal wear and damage of the equipment, reduce productivity, and affect the normal operation of the whole set of equipment. Since its establishment, the company's products have been sold to all parts of the country and are deeply welcomed by new and old customers. Based on the principle of good faith, the company has established long-term cooperative relations with many customers. Now our company is further strengthening the technical training of employees, improving the technical level of employees, injecting high technology into products, and striving for better quality and more affordable products. Our company can also design and manufacture non-standard special-shaped parts of conveyor to meet the needs of customers. We have accumulated rich experience in this regard.

UNIT:MM

Balt Width(B) | Roller | Bearing No. | Idler Weight | H | H1 | H2 | E | A | P | Q | d | Support Weight | ||

D | L | L1 | ||||||||||||

500 | 89 | 200 | 230 | 204 | 9.90 | 220 | 135.5 | 346 5 | 912 | 740 | 170 | 130 | M12 | 25.99 |

650 | 89 | 250 | 280 | 204 | 10 36 | 235 | 135.5 | 375 | 1055 | 890 | 170 | 130 | M12 | 27.98 |

108 | 205 | 265 | 146 | 1100 | ||||||||||

800 | 89 | 315 | 323 | 204 | 10.76 | 245 | 135.5 | 400 | 1183 | 1090 | 170 | 130 | M12 | 32.89 |

108 | 342 | 205 | 16.98 | 270 | 146 | 440 | 1243 | 34.07 | ||||||

1000 | 108 | 380 | 405 | 305 | 18.30 | 300 | 159 | 487.5 | 1439 | 1290 | 220 | 170 | M16 | 44.41 |

133 | 412 | 305 | 26 82 | 325 | 173.5 | 505 | 1520 | |||||||

1200 | 108 | 465 | 470 | 205 | 335 | 176 | 544 | 1639 | 1540 | 260 | 200 | M16 | 100 | |

133 | 305 | 360 | 190.5 | 590 | 1715 | 120 | ||||||||

159 | 306 | 390 | 207.5 | 607 | 1717 | 125 | ||||||||

1400 | 108 | 530 | 560 | 205 | 350 | 184 | 590 | 1841 | 1740 | 280 | 220 | M16 | 102 | |

133 | 305 | 380 | 198 5 | 635 | 1887 | 130 | ||||||||

159 | 306 | 410 | 315.5 | 653 | 1895 | 136 | ||||||||

1600 | 159 | 600 | 630 | 306 | 450 | 247 | 780 | 2050 | 1980 | 300 | 240 | M16 | 179 | |

159 | 308 | 450 | 247 | 780 | 2050 | 194 | ||||||||

Belt Width(B) | D | D1 | D2 | L1 | L2 | Bearing No. | Idler Weight | H | H1 | H2 | E | A | P | Q | d | Support Weight |

800 | 108 | 89 | 133 | 250 | 340 | 205 | 6.25 | 270 | 146 | 395 | 1150 | 1090 | 170 | 130 | M12 | 40.08 |

133 | 108 | 159 | 305 | 296 | 159.6 | 422 | ||||||||||

1000 | 133 | 108 | 159 | 315 | 415 | 305 | 9.12 | 325 | 173.5 | 478 | 1350 | 1290 | 220 | 170 | M16 | 47.28 |

159 | 108 | 159 | 306 | 355 | 190.5 | 508 | ||||||||||

1200 | 133 | 108 | 176 | 380 | 500 | 306 | 12.44 | 360 | 190.5 | 548 | 1600 | 1540 | 260 | 200 | M16 | 60.62 |

159 | 133 | 194 | 306 | 13.79 | 390 | 207.5 | 578 | 59.20 | ||||||||

1400 | 133 | 108 | 176 | 465 | 550 | 305 | 11.84 | 380 | 198.5 | 584 | 1800 | 1740 | 280 | 220 | M16 | 66.40 |

159 | 133 | 194 | 306 | 14.63 | 410 | 215.5 | 615 | 66.98 | ||||||||

1600 | 159 | 133 | 219 | 530 | 600 | 307 | 450 | 225.5 | 750 | 1980 | 2050 | 300 | 240 | M16 | ||

308 | ||||||||||||||||

1800 | 159 | 133 | 219 | 600 | 670 | 307 | 465 | 225.5 | 770 | 2180 | 2250 | 340 | 270 | M16 | ||

308 |