Fabric Belt Stripper

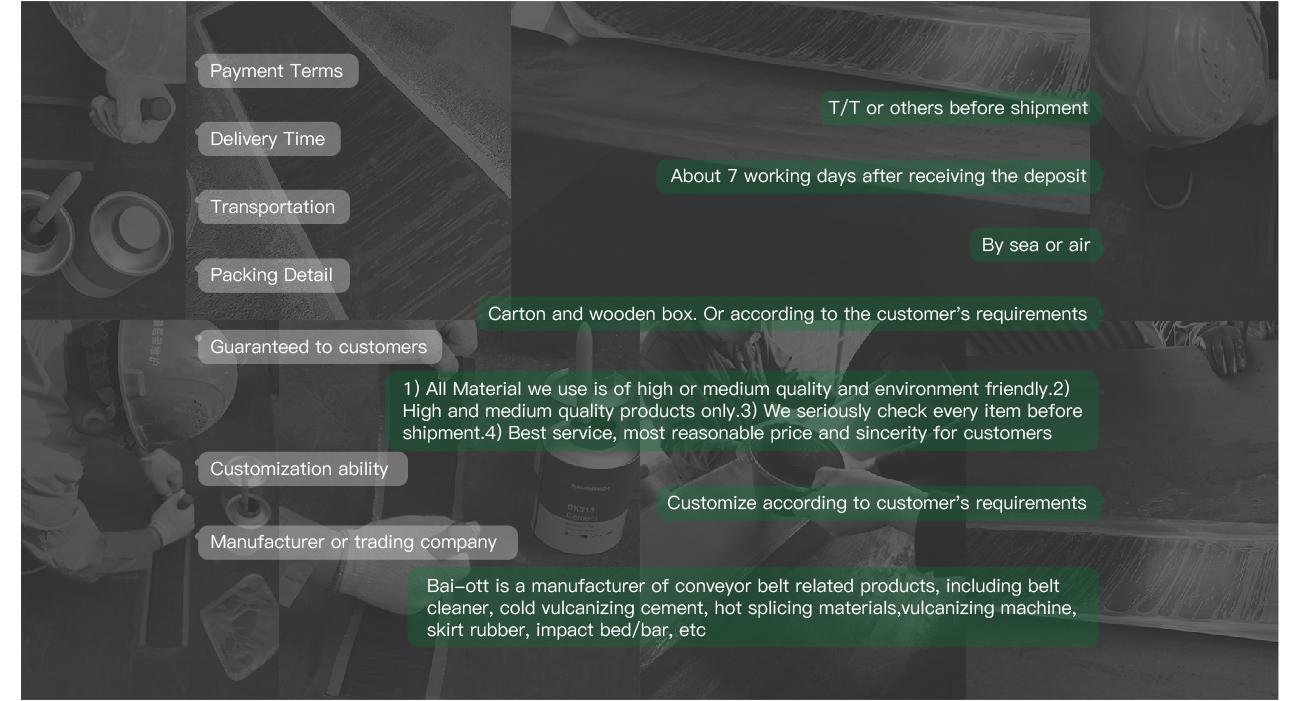

Brand: BAI-OTT or OEM

Feature: High Efficiency

Application:Conveyor Belt Lacing, Belt Repair, Belt joint

Sample:Provide

Product Inspection:Available

MOQ: 1 Set

Lead time:Ready to ship in stock

View more Conveyor Splicing Tools from BAI-OTT

Description

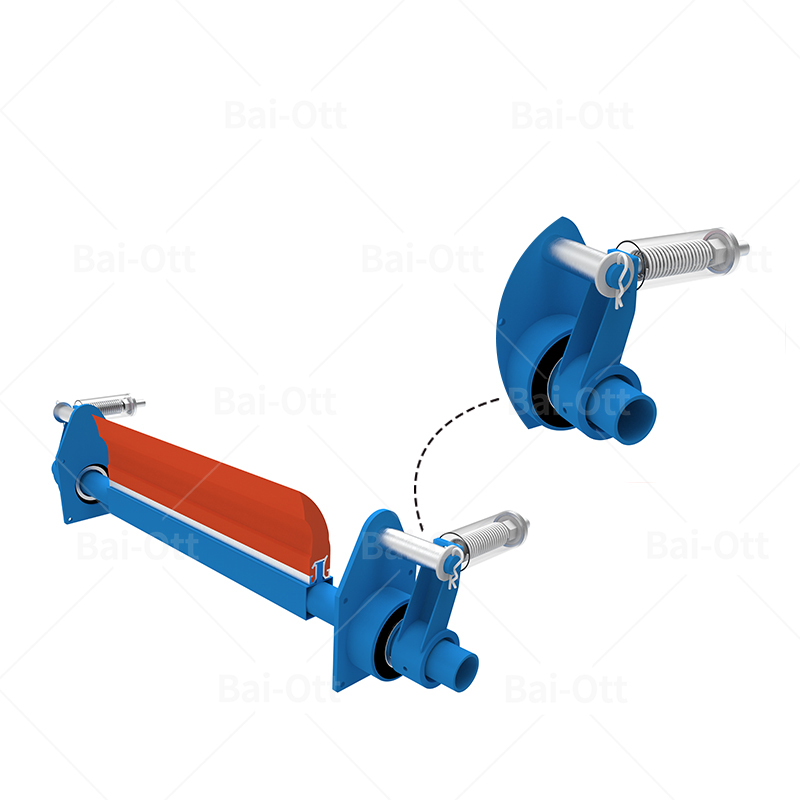

The fabric rope belt stripper is used to strip fabric core conveyor belt. The machine is applied to separation of cover rubber and canvas, cover rubber and fabric rope and canvas of various fabric core conveyor belts.The fabric rope belt stripper is electric and easy to operate with its special design, which ensures the maximum productivity for you to do repairing and minimizes the downtime.The stripper can save your worker costs and strength because it can help you strip the belt by itself.

Belt conveyors are widely used in the development and transportation of coal mines, iron mines and other minerals, as well as bulk cargo loading and unloading at ports and docks; The conveyor belt is the bearing component of the belt conveyor. Long-distance transportation and long-time operation also bring inherent disadvantages to the belt conveyor: once the belt is broken, it will have a serious impact on the production: if it is light, the local production line will be stopped; The serious one will cause the production to stop completely, so the conveyor belt is damaged and needs to be repaired as soon as possible.

The repair method of belt head has always been mainly manual, using angle grinder, cutter, puller and other methods to cut off the damaged or broken part of the belt, or peel off the rubber layer of the belt to be repaired to expose a whole row of steel wire rope inside. If the belt is newly connected, the rubber layer at least one meter long at both ends of the belt shall be stripped off, and then the rubber vulcanization repair shall be carried out. This method has high labor intensity and low stripping efficiency. Several people work in turn, and it can be completed in more than ten hours at the fastest.

1. BAI-OTT D1200-1513 conveyor belt automatic stripping machine adopts ultra-high pressure hydraulic cutting technology to break and peel the rubber layer of the conveyor belt without damaging the steel wire rope in the belt.

2. The specially designed high-pressure water rotary injection mechanism and recovery device enable the rubber to be stripped quickly while maintaining low-temperature brittleness.

3. According to the width of the conveyor belt and the length to be stripped, the motion parameters of the automatic stripping mechanism are set on the controller to complete the line by line scanning stripping operation.

4. Greatly improve the efficiency and shorten the shutdown time. Manual stripping requires more than ten hours. The automatic belt head stripping equipment can be completed in about 1 ~ 2 hours.

5. There are explosion-proof models and ordinary models, which can provide you with different selection needs.

Advantage

High working efficiency

Long service life

Easy to operate

We specialize in this field for more than 20 years and have good advantage of quality control.

We’re the top manufacturer and supplier in China market .

Specifications

Instruction:

1. First of all, the fabric rope of the pickup head should be transported with adhesive tape, and remove the rubber on both sides and fix the adhesive tape.

2. Deciding the area you want to strip, install the head of the stripper and adjust the tightness of the press wheel bolt, press down the handle, connect the towing frame through the fabric rope for movement, and drive the machine to make the rubber off the fabric rope, and end the picking head.

Features:

1. Large stripping area and fast speed, which greatly reduces the labor and saves time.

2. Light weight and easy to operate

3. Stable operation

4. High efficiency

5. Low labor intensity

6. Long service life

Technical parameters:

| Order No. | Voltage | Power | Weight |

| R050002 | 220V-50HZ | 1.6KW | 19kg |