Hand Rasp

Brand: BAI-OTT or OEM

Feature: High Efficiency

Application:Conveyor Belt Lacing, Belt Repair, Belt joint

Sample:Provide

Product Inspection:Available

MOQ: 1 Set

Lead time:Ready to ship in stock

View more Conveyor Splicing Tools from BAI-OTT

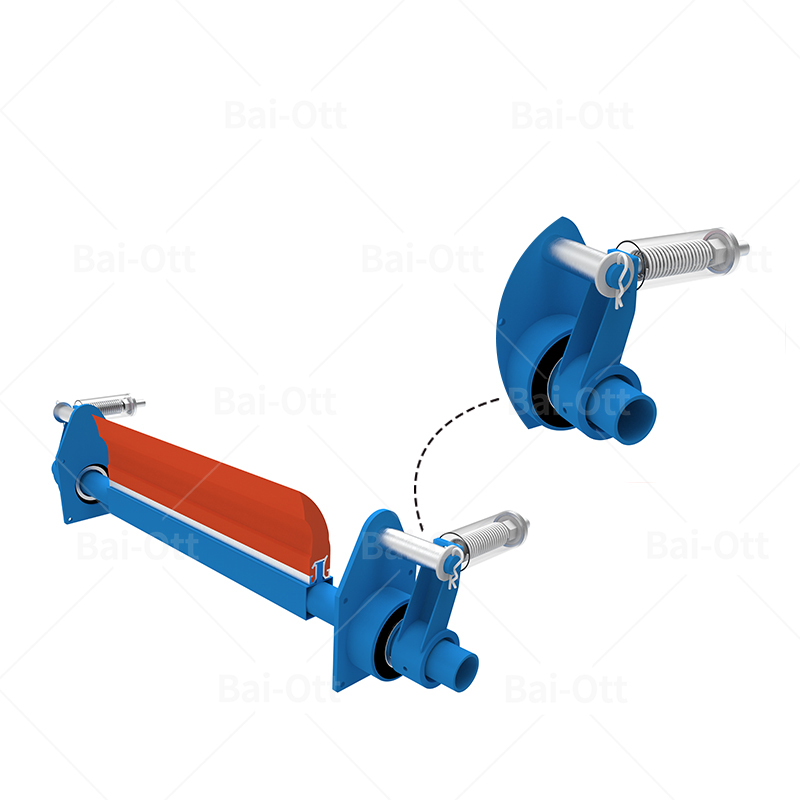

Length:200(mm)

Weight:163(g)

Description

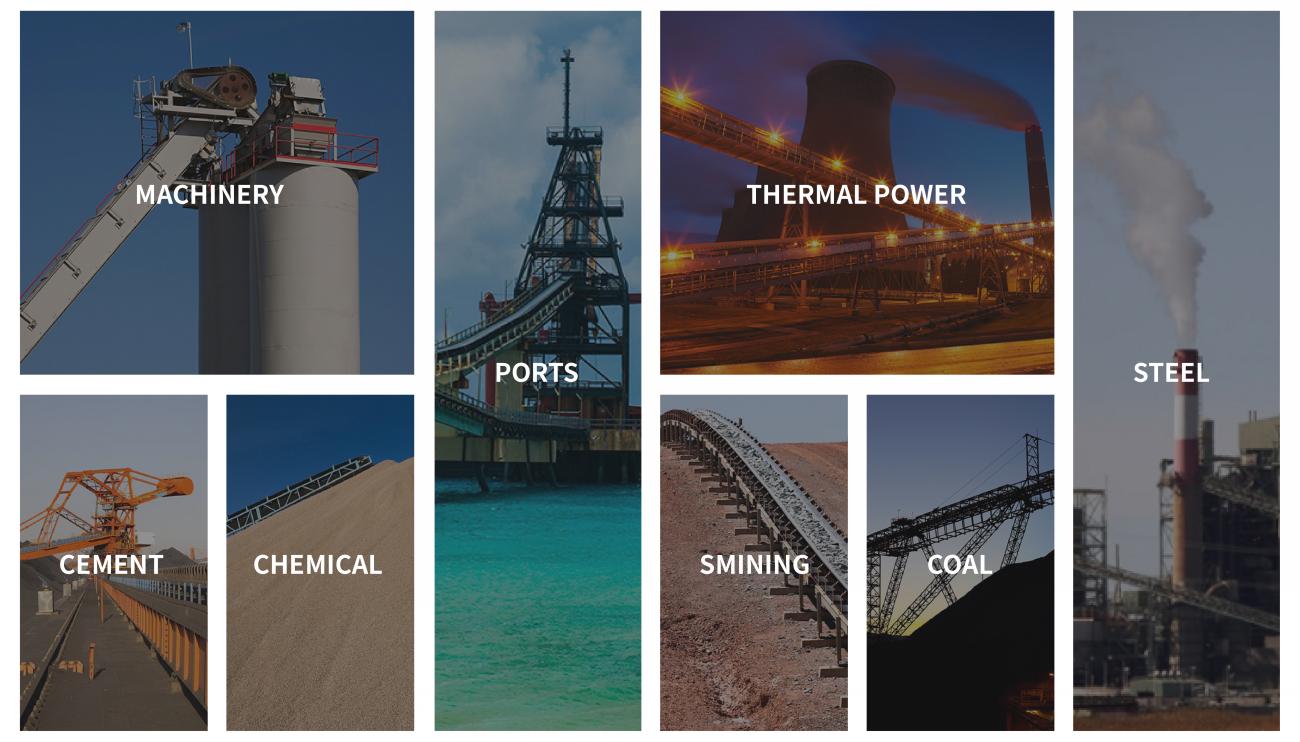

The handheld rasp is applied to repairing conveyor belt. The brush head is made of stainless steel with multiple steel needles. And the wooden handle make it easy to hold and operate. The bufffing rasp has the features of long service life in tough surface, hard material and construction, which ensure the best working effect.The handheld can be applied in different areas, such as mining, port, power plant, household application ect.

The handheld rasp is generally composed of metal shaft, brush wire attachment (plastic pipe, nylon pipe, etc.) and brush wire. The processing procedures include: axle, casing (pouring), drilling, wool planting and flat wool. For the special-shaped brush roller, when the machine planting of wool cannot be completed, the wool material shall be planted manually. The brush roller is applicable to five industries: food processing industry, glass ceramics industry, metal processing industry, polishing and cleaning industry and textile machinery. Firstly, cut the steel shaft into appropriate size, put it on the machine bed, turn out the blank, weld, reinforce and straighten it, and then make the prototype of roll core through lathe; Then, according to different requirements, the sleeve is made outside the prototype of the roll core or put into the mold for direct injection molding. In this way, the basic shape of a brush roll body has been formed. Put the roller body blank after injection molding or casing on the machine tool for fine machining according to the size required by the drawing, and carry out subsequent treatment according to different process requirements. For example, for fine grinding of the rubber coated roller core, the shaft head needs to be made with different keyways or interfaces. Drilling and hair planting brush roller - use CNC punching equipment to punch the finished brush roller. The depth and density of the hole are set separately according to different requirements. Put the punched brush roller on the full-automatic CNC hair planting machine or semi-automatic horseshoe buckle hair planting machine for hair planting; After the hair planting is completed, the hair is sheared by the drum shearer, so that the brush wire on the surface of the brush roller is cut flat.

Advantage

Good strength and short manufacturing cycle.

The production process is simple. Now it is the main production mode of high temperature resistant nylon wire brush roller.

A wool planting method introduced from abroad, which makes the abrasive wire into a metal strip that can be wound, and then wound on the grinding roller. It can be customized according to the length of the grinding roller. Now it is the main production mode of abrasive wire brush roller.

The sanding roller produced by the company is spliced with aluminum alloy cylinder, and the brush roller of any length can be customized; The high-strength aluminum alloy substrate can make the hair planting density the highest, and the most cutting-edge hair planting technology is used. It does not depilate, nor does it crack and grow like nylon; The roller body can accurately check the dynamic balance.

High working efficiency

Long service life

Excellent working result

Stainless steel and good looking

We specialize in this field for more than 20 years and have good advantage of quality control.

We’re the top manufacturer and supplier in China market .

Specifications

Firstly, cut the steel shaft into appropriate size, put it on the machine bed, turn out the blank, weld, reinforce and straighten it, and then make the prototype of roll core through lathe;

Then, according to different requirements, the sleeve is made outside the prototype of the roll core or put into the mold for direct injection molding. In this way, the basic shape of a brush roll body has been formed. Put the roller body blank after injection molding or casing on the machine tool for fine machining according to the size required by the drawing, and carry out subsequent treatment according to different process requirements. For example, for fine grinding of the rubber coated roller core, the shaft head needs to be made with different keyways or interfaces.

Finally, put the punched brush roller on the full-automatic numerical control wool planting machine or semi-automatic horseshoe buckle wool planting machine for wool planting; After the hair planting is completed, the hair is sheared by the drum shearer, so that the brush wire on the surface of the brush roller is cut flat.

Technical parameters:

| Order No. | Length | Weight |

| R080340 | 340mm | 900g |

| R080098 | 9*28*98mm | Spare |