Ceramic Rubber Polyurethane Composite Lining Board

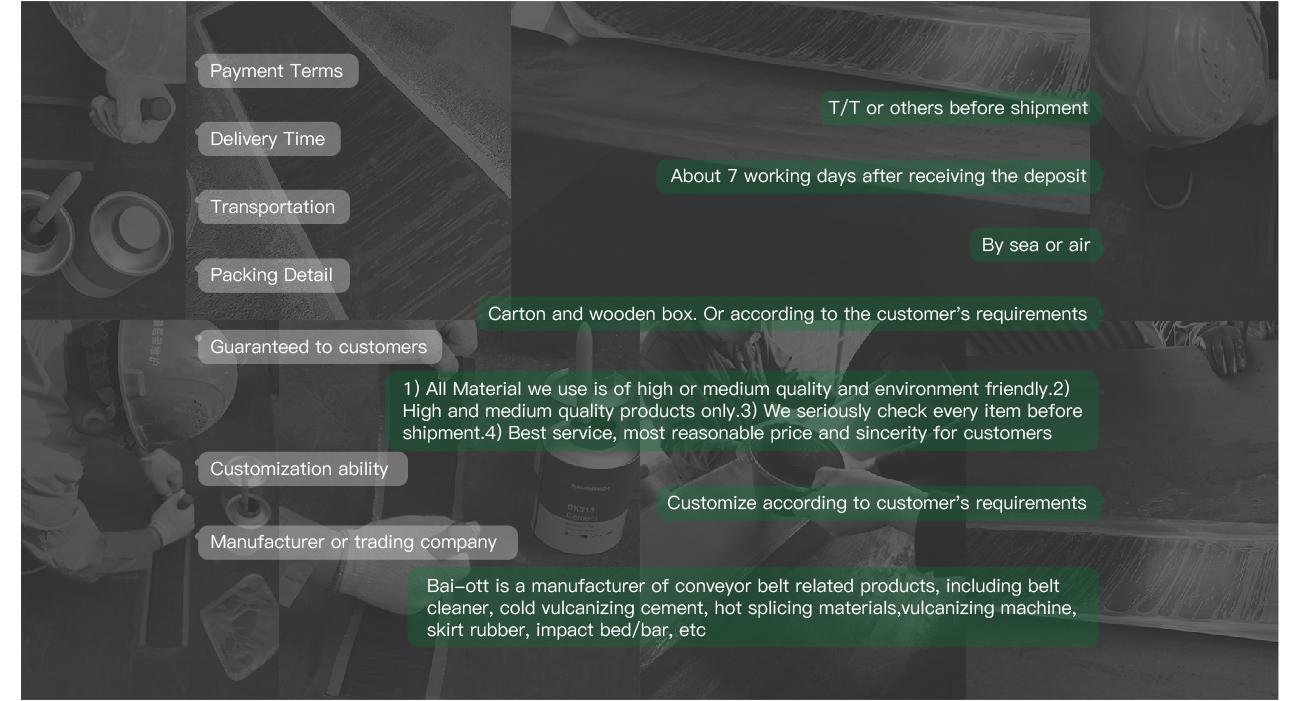

Brand: BAI-OTT or OEM

Bending Strength(Mpa): >280

Feature: Abrasion and impact resistance

Size: Available

Material: Ceramic+Rubber+Polyurethane

Sample: Provide

MOQ: 1 Square Meter

Lead time:Ready to ship in stock

View more Ceramic Lining from BAI-OTT

Description

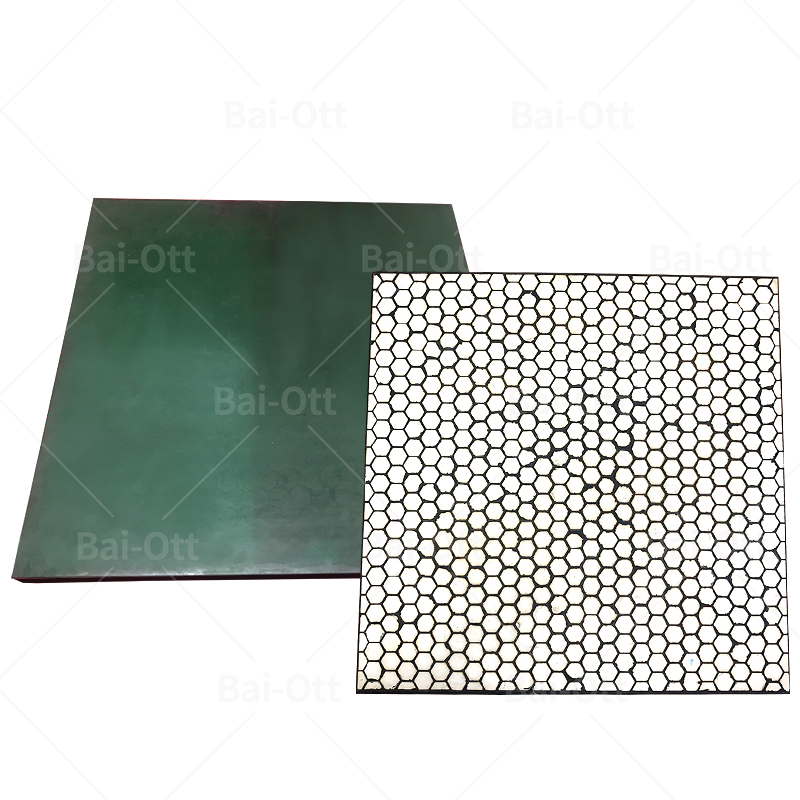

Ceramic Rubber Polyurethane Composite Lining Board

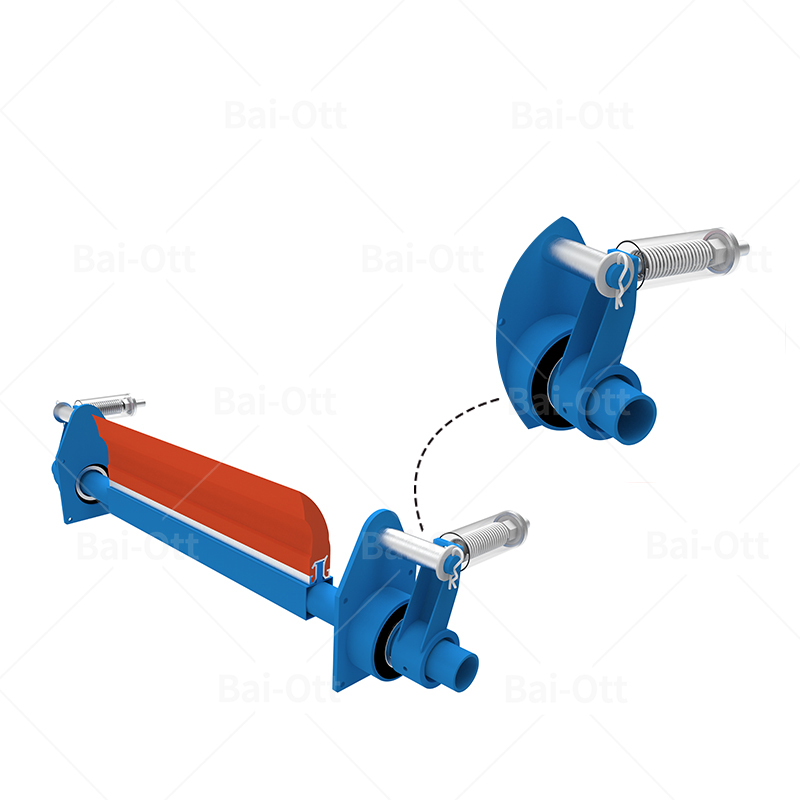

The Ceramic Rubber Polyurethane Composite Lining Board is formed by vulcanizing the anti-wear corundum ceramic and the steel plate into a lining plate through polyurethane. It has strong wear resistance, impact resistance and corrosion resistance.

The scope of application of the anti-wear liner:

1. Adaptation temperature: -40~140℃

2. Applicable objects: anti-wear lining of various equipment and pipelines

3. Connection method: Bolt connection, Welding,Bonding

Impact resistance: good buffering performance, which can effectively buffer the impact of ore falling from a high place. The pure anti-wear ceramic lining plate has anti-wear performance because the main raw material for production is alumina, but the toughness is insufficient. When the impact reaches an appropriate level, the anti-wear composite lining plate is used.

Convenient construction: there is no gap after the lining is installed. The rubber composite lining can be twisted and cut, and is suitable for installing various special-shaped equipment.

Advantage

Non-stick and non-blocking: Due to the high strength and anti-corrosion properties of ceramics, the phenomenon of equipment sticking and blocking is effectively solved. The traditional nylon board often sticks to the material, which affects the work efficiency.

The ceramic-rubber composite liner has strong anti-wear, impact resistance and anti-corrosion properties. Rubber elastomer has excellent vibration damping effect, which can reduce the noise generated during material conveying.

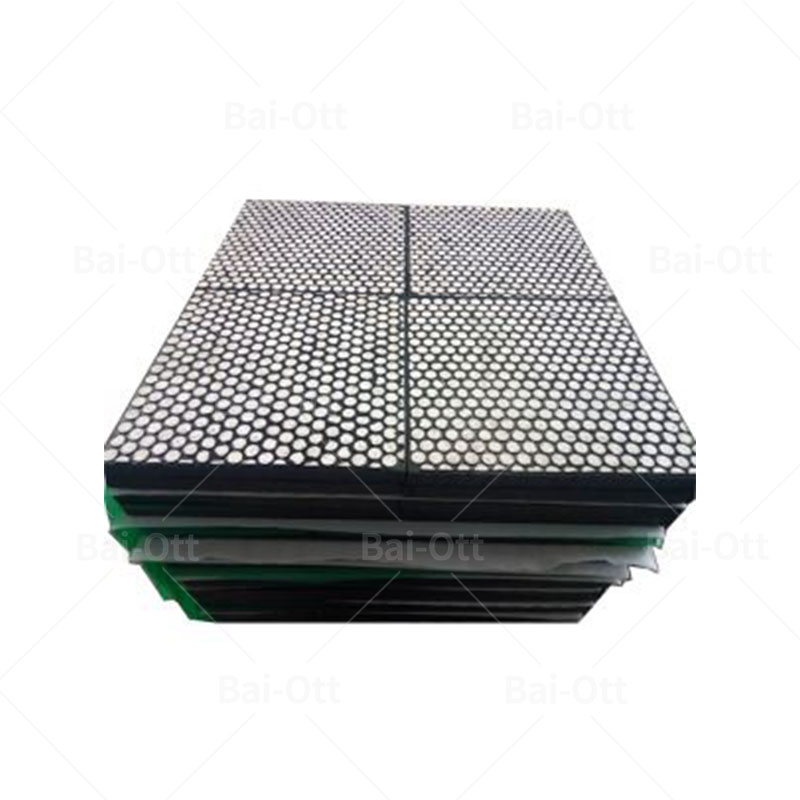

The ceramic-rubber composite liner is lower in density than steel plate, light in weight, and because of its anti-wear performance, it does not need to be replaced frequently, saving a lot of time and cost for enterprises.

Specifications

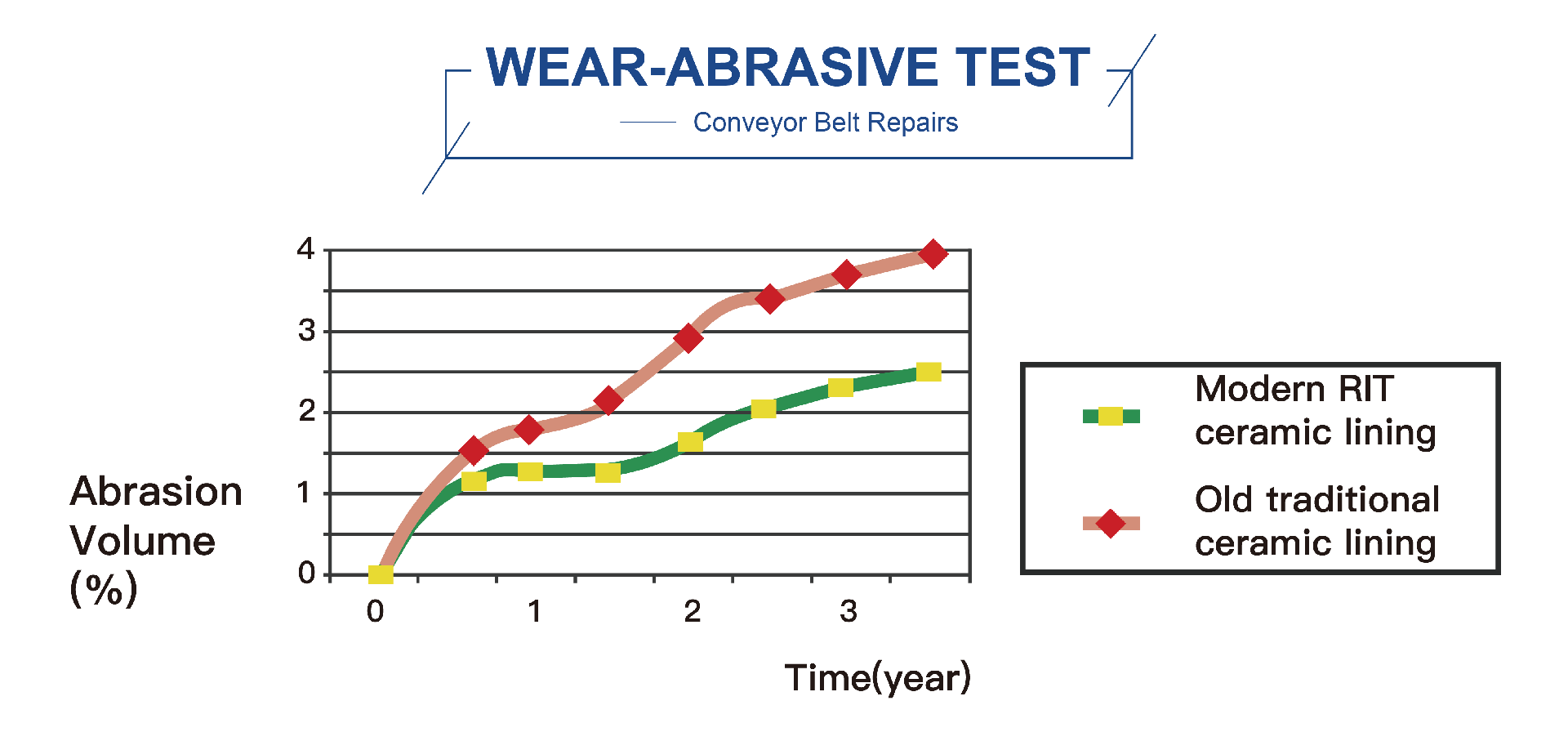

The use of wear-resistant ceramics can greatly save maintenance time and costs, and at least increase the service life of the equipment by more than 10 times.

| Size(mm) | Length/Width(mm) | Ceramic Thickness(mm) | Rubber Thickness(mm) | Rubber Thickness(mm) |

| 250×250×15 | 250/250 | 5 | 5 | 5 |

| 300×300×16 | 300/300 | 8 | 4 | 4 |

| 500×500×25 | 500/500 | 15 | 4 | 6 |

| 500×600×30 | 500/600 | 20 | 6 | 4 |

| 600×300×35 | 600/300 | 25 | 6 | 4 |

| 400×500×38 | 400/500 | 25 | 7 | 6 |

| 300×400×50 | 300/400 | 30 | 12 | 8 |

| 300×300×63 | 300/300 | 50 | 7 | 6 |

| 300×400×130 | 300/400 | 100 | 18 | 12 |

Further dimensions on demand.

Ceramic Tile Specifications | |

AL2O3(%) | 95±0.5 |

Bending Strength(Mpa) | >280 |

Fracture Toughness(MPam1/2) | >3.9 |

Rockwell Hardness(HRA) | >88 |

Wear Volume(cm3) | <0.3 |

Density(g/cm3) | >3.7 |

Items | Data |

Tensile Strength(Mpa) | ≥14 |

Break Extension(%) | ≥350 |

Shore Hardness(degree) | 55-65 |

Break Permanent Deformation(%) | ≤24 |

Rubber and Ceramic Adhesion Force(Mpa) | ≥3.0 |

Temperature Resistance(°C) | ≤100 |

The rubber and ceramic composite wear-resistant products is a customized product, it can be made in various shapes, selected composite material according liner wear of various thicknesses, forming a strong wear layer.

Square bricks: 10x10x2~10mm, 17.5x17.5x2~15mm,20x20x2~15mm,33x33x7~25mm, etc.

Ceramic plate: 100x100x6~50mm, 150x100X6~50mm, etc.

Hexagonal tiles: S12xT3~20mm, S19xT6~25mm

Ceramic tiles: 40x40x40mm, 32x32x22mm, 38x38x38mm, etc.

Ceramic cylinder/rod: 6x6mm, 15x15mm, 20x20mm, 31x31mm, 40x40mm, 50x50mm, etc.

The unique toughening formula forms a strong crystal bond, which greatly enhances the impact resistance of alumina ceramics, which is 3 to 5 times that of general standard wear-resistant ceramics.

The raw materials of the rubber and ceramic composite wear-resistant are high-purity alpha alumina and crystal growth inhibitor. Powder prepared using the most advanced powder technology to ensure flowability of the granulated powders made uniform distribution possessed good.