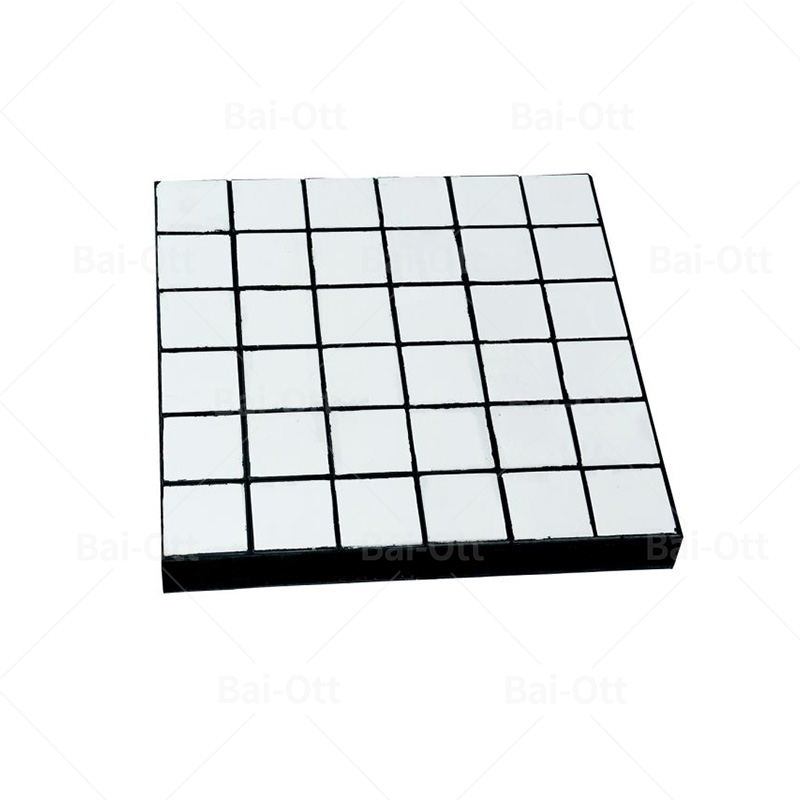

Rubber Wear-resistant Ceramic Liner

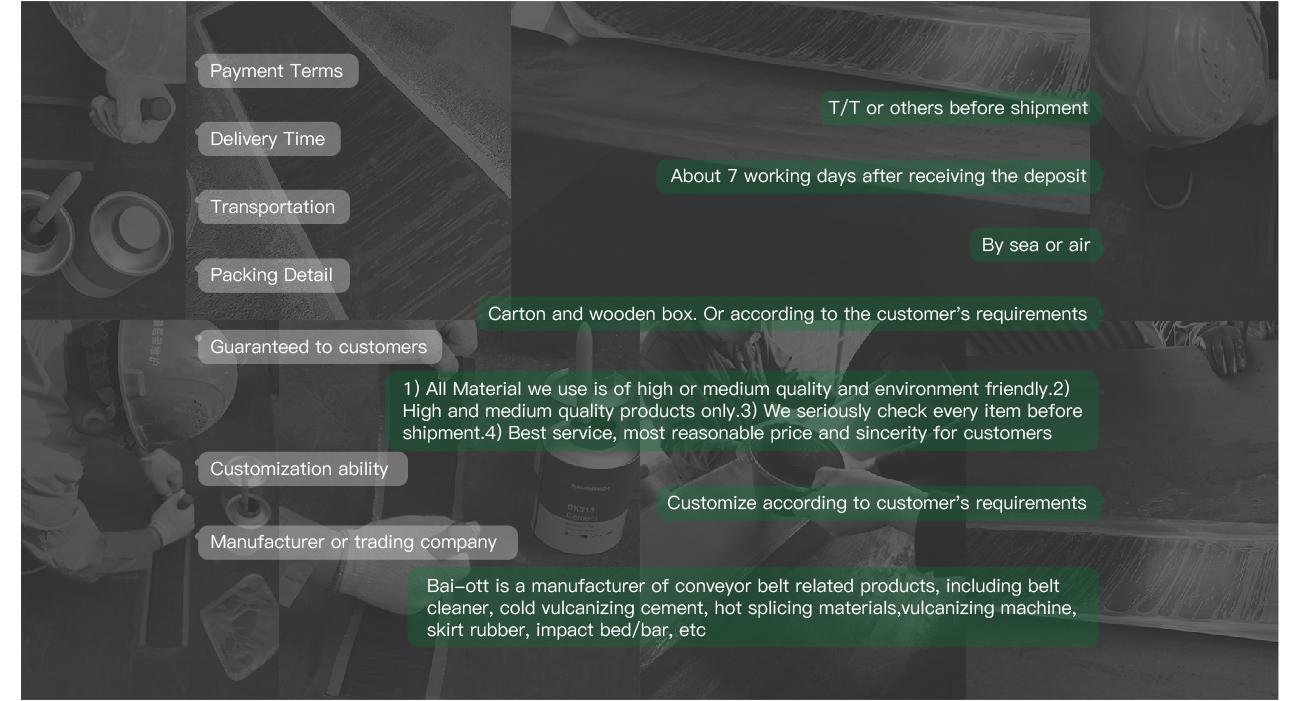

Brand: BAI-OTT or OEM

Bending Strength(Mpa): >280

Feature: Abrasion and impact resistance

Size: Available

Material: Ceramic+Rubber+Polyurethane

Sample: Provide

MOQ: 1 Square Meter

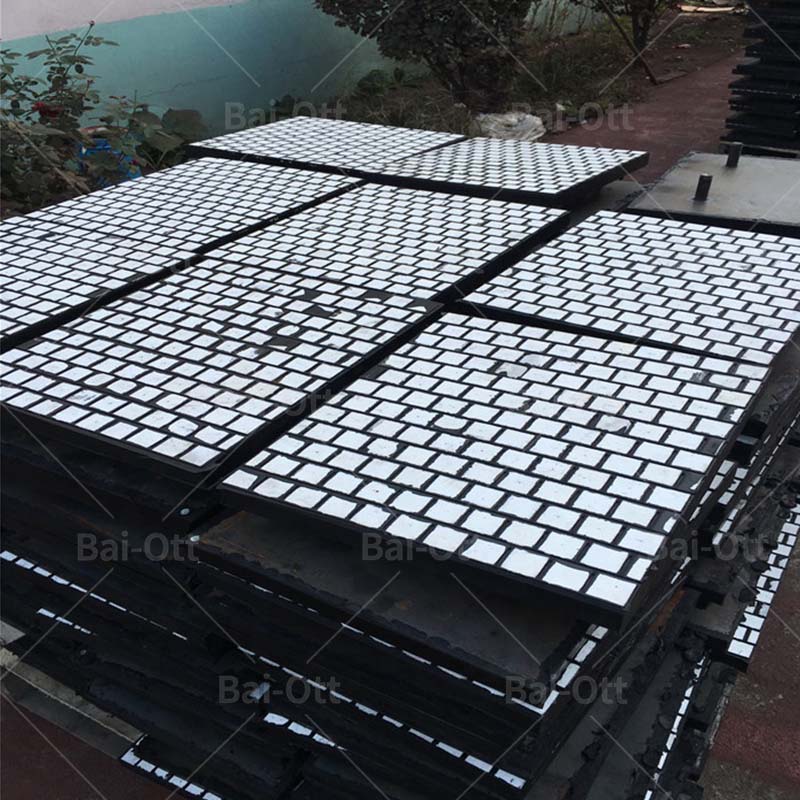

Lead time:Ready to ship in stock

View more Ceramic Lining from BAI-OTT

Description

Rubber Wear-resistant Ceramic Liner

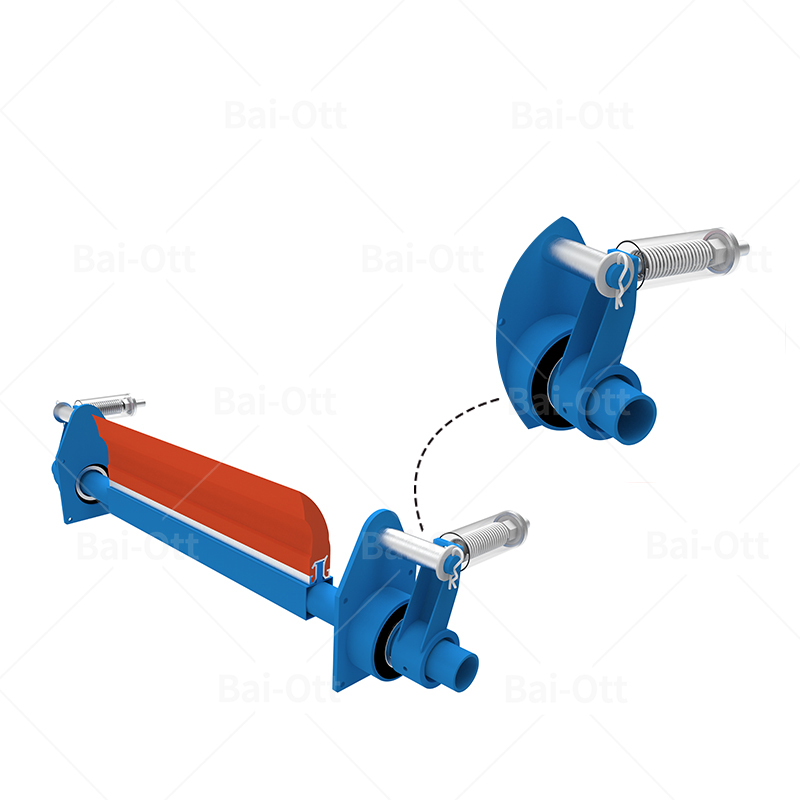

The products mainly include cylinder rubber lifting strips, cylinder linings, end lifting strips, etc. It is made of composite vulcanization of high wear-resistant rubber and high-hardness wear-resistant materials. It has the characteristics of super strong impact, high wear resistance, long service life, convenient installation and replacement, saving power consumption and reducing noise.

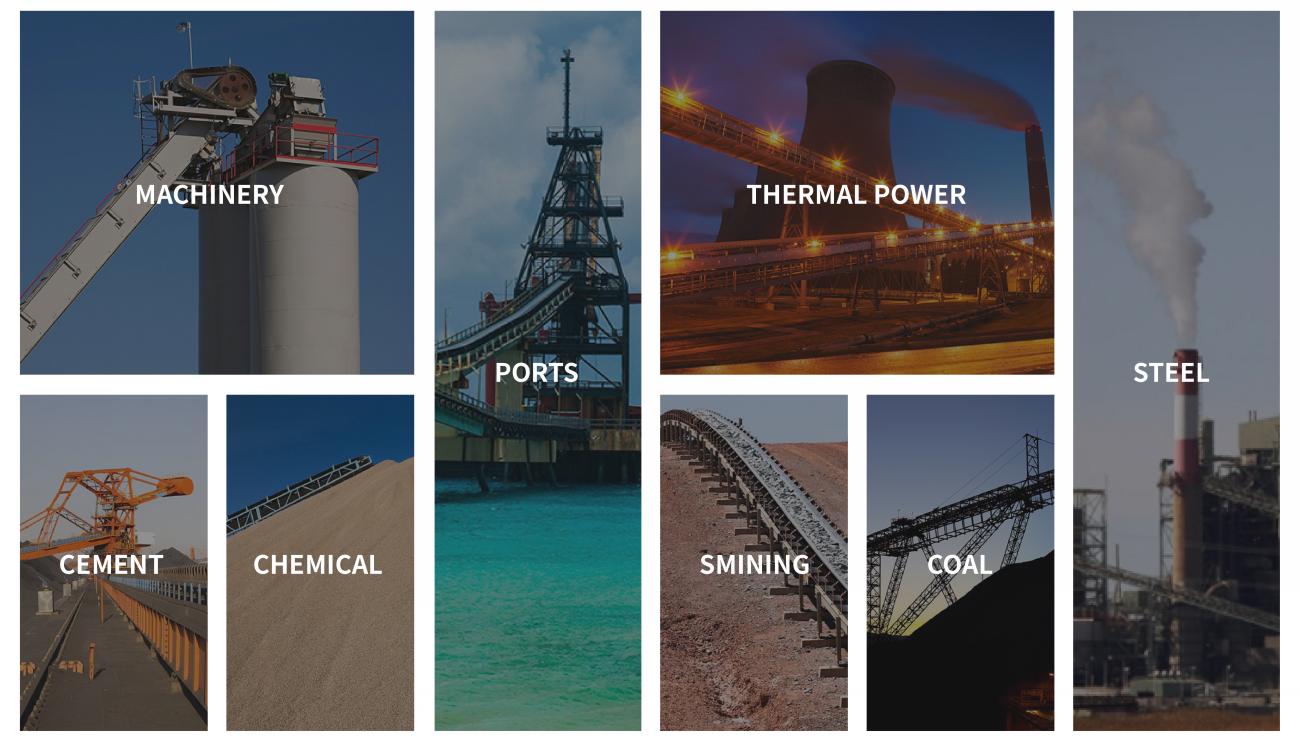

Typical field of use: Highest resistance for applications with impact energies and abrasion ;For heavy to medium duty applications in mining,gravel,sand and stone breaking mills and other industrial; In applications like bunkers,chutes,loading points, slides,hoppers ,silos,ect.

The wear resistance of wear-resistant ceramic pipe mainly depends on the wear resistance of lining wear-resistant ceramics, and wear resistance refers to the ability of materials to resist mechanical wear, which is mainly determined by the hardness, strength and roughness of materials.

High hardness, high strength and smooth surface are the reasons for the wear resistance of the wear-resistant ceramic pipe. On this basis, there are also integrated forming, staggered joint connection and other methods to reduce the scouring of gas and powder on the wear-resistant ceramic pipe, so that the wear resistance of the wear-resistant ceramic pipe can reach a new level.

Advantage

Hardness: the hardness of the material reflects the ability of the material to resist the material pressing into the surface. The higher the hardness, the shallower the depth of material intrusion, the smaller the volume of wear and the higher the wear resistance. The alumina content of wear-resistant ceramics exceeds 92% and the hardness reaches hra85 or above, which is the basis of wear resistance of wear-resistant ceramic tubes.

Strength: high strength, which can provide good support for wear resistance and give full play to the ability of anti-wear and hard wear resistance, that is, strength and hardness complement each other. The bending strength of wear-resistant ceramics is 300-450 MPa and the compressive strength is 1200-2500 MPa, which further strengthens the wear resistance of wear-resistant ceramic pipes.

Roughness: the smaller the roughness value, the higher the fatigue wear resistance. Under certain circumstances, the ceramic surface roughness is related to the thickness of powder particles. Wear resistant ceramics have been polished for many times, and are supported by high-quality fine powder. The smoothness is very high, which adds a third guarantee to the wear resistance of wear-resistant ceramic tubes.

Specifications

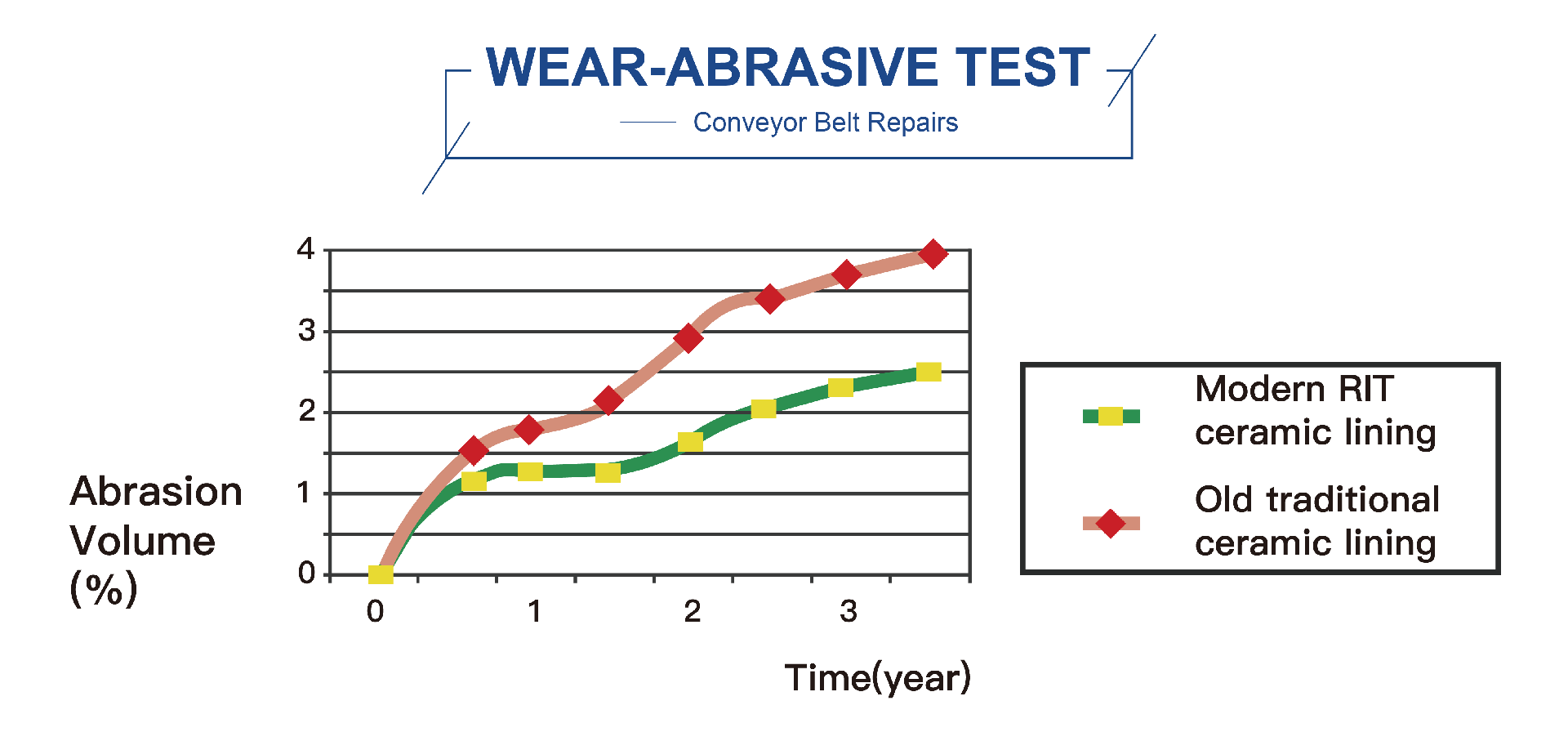

The use of wear-resistant ceramics can greatly save maintenance time and costs, and at least increase the service life of the equipment by more than 10 times.

| Size(mm) | Length/Width(mm) | Ceramic Thickness(mm) | Rubber Thickness(mm) | Rubber Thickness(mm) |

| 250×250×15 | 250/250 | 5 | 5 | 5 |

| 300×300×16 | 300/300 | 8 | 4 | 4 |

| 500×500×25 | 500/500 | 15 | 4 | 6 |

| 500×600×30 | 500/600 | 20 | 6 | 4 |

| 600×300×35 | 600/300 | 25 | 6 | 4 |

| 400×500×38 | 400/500 | 25 | 7 | 6 |

| 300×400×50 | 300/400 | 30 | 12 | 8 |

| 300×300×63 | 300/300 | 50 | 7 | 6 |

| 300×400×130 | 300/400 | 100 | 18 | 12 |

Further dimensions on demand.

Ceramic Tile Specifications | |

AL2O3(%) | 95±0.5 |

Bending Strength(Mpa) | >280 |

Fracture Toughness(MPam1/2) | >3.9 |

Rockwell Hardness(HRA) | >88 |

Wear Volume(cm3) | <0.3 |

Density(g/cm3) | >3.7 |

Items | Data |

Tensile Strength(Mpa) | ≥14 |

Break Extension(%) | ≥350 |

Shore Hardness(degree) | 55-65 |

Break Permanent Deformation(%) | ≤24 |

Rubber and Ceramic Adhesion Force(Mpa) | ≥3.0 |

Temperature Resistance(°C) | ≤100 |

The rubber and ceramic composite wear-resistant products is a customized product, it can be made in various shapes, selected composite material according liner wear of various thicknesses, forming a strong wear layer.

Square bricks: 10x10x2~10mm, 17.5x17.5x2~15mm,20x20x2~15mm,33x33x7~25mm, etc.

Ceramic plate: 100x100x6~50mm, 150x100X6~50mm, etc.

Hexagonal tiles: S12xT3~20mm, S19xT6~25mm

Ceramic tiles: 40x40x40mm, 32x32x22mm, 38x38x38mm, etc.

Ceramic cylinder/rod: 6x6mm, 15x15mm, 20x20mm, 31x31mm, 40x40mm, 50x50mm, etc.

The unique toughening formula forms a strong crystal bond, which greatly enhances the impact resistance of alumina ceramics, which is 3 to 5 times that of general standard wear-resistant ceramics.

The raw materials of the rubber and ceramic composite wear-resistant are high-purity alpha alumina and crystal growth inhibitor. Powder prepared using the most advanced powder technology to ensure flowability of the granulated powders made uniform distribution possessed good.